4.10

Mounting the motor

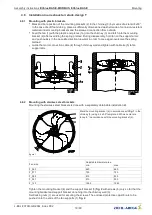

Motors design MK

Fastening to

fi

xed motor

fl

ange, see assembly of axial fans / fans of design A, D .. and assembly of

radial fans of design RH.

•

If the motor is used to drive fan impellers or other components, please note the maximum

permissible speeds of the impeller or the component to be driven.

•

The max. permissible mass of the impeller or the component to be driven must be inquired from

and con

fi

rmed in writing by ZIEHL-ABEGG.

Design K (with rotor

fl

ange) or D (with offset rotor

fl

ange) as a drive for fans:

•

During assembly of the fan impellers or other components, no inadmissible force may be applied to

the motor bearing.

•

Centre the fan impeller accurately and mount without tension on the rotor

fl

ange, the fan wheel

must lie

fl

at.

•

Use suitable screws for fastening the fan impeller on the rotor

fl

ange and

fi

t as suitable screw lock.

•

Every screwing case must be tested for suitability.

•

The permissible area pressing of the steel

fl

ange may never be exceeded (depending on the

contact surface).

•

Too great a screw overhang is not permitted and can lead to scraping or blocking of the rotor on the

fi

xed motor

fl

ange.

•

Motors are not balanced as standard, a complete balancing with mounted fan impeller is necessary.

The balancing must be done on the fan impeller. The pertinent regulations must be observed.

Permissible tightening torques M

A

Motor size

D

G

Thread size

M6

M8

Property class 8.8, friction coefcient

µ

ges = 0.12

9.5 Nm

23 Nm

Screw penetration

≥

0.83 x d

≥

0.83 x d

Max. permissible screw overhang

1.0 mm

1.5 mm

5

Electrical installation

5.1

Safety precautions

Danger due to electric current

•

Work on electric components may only be carried out by trained electricians or by persons

instructed in electricity under the supervision of an electrician in accordance with electrical

engineering regulations.

•

The 5 electrical safety rules must be observed!

•

It is forbidden to carry out work on electrically live parts! Even after disconnection, the dc-link is still

live. Always wait at least 3 minutes.

•

Cover neighbouring electrical equipment during installation work.

•

Cable glands made out of metal are not allowed in plastic terminal boxes due to lack of potential

equalisation.

•

Other measures may be necessary to achieve safe electrical isolation.

•

Connect fan only to electrical circuits that can be disconnected with an all-pole isolating switch.

•

Operating the device with the housing cover removed is prohibited because energized, exposed

parts are present inside the device. Disregarding this regulation can lead to severe personal injury.

•

The

fi

nal application must ensure that the fundamental health and safety requirements are met.

•

The device owner is responsible for the EMC of the entire plant according to the locally applicable

standards.

•

Electrical equipment must be checked regularly: Loose connections are to be re-tightened and

damaged cables must be replaced immediately.

Assembly instructions

ECblue BASIC-MODBUS, ECblue BASIC

Electrical installation

L-BAL-F079D-GB 2044 Index 002

Part.-No.

21/80