21

4. Service Guide

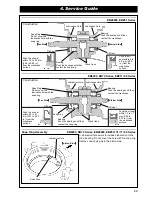

4-7 Crankcase Assembling

Bearings, snap ring, oil seal configuration and installation position differ depending on type.

Properly install each part and reassemble the crankcase referring to the corresponding type’s drawing.

For bearing and oil seal installation, refer to the explanation on page 23.

HB23 Series, HBZ26 Series

EBZ30 Series

EB4300

【

【【

【

Fan Side

】

】】

】

Push the oil seal within 0 to

0.5 mm (0.02 in.) from the

crankcase surface.

Oil Seal

【

【【

【

Starter Side

】

】】

】

Oil Seal

Align the oil seal surface with

the crankcase surface.

Bearing

Push the bearings until they

contact the snap ring.

Bearing

Push the bearings until they

contact the crankcase.

Snap Ring

Crank Case

Construction

Push the oil seal within 0 to

0.5 mm (0.02 in.) from the

crankcase surface.

Oil Seal

【

【【

【

Fan Side

】

】】

】

【

【【

【

Starter Side

】

】】

】

Bearing

Push the bearings until they

contact the crankcase.

Snap Ring

Do not cover the lubrication

hole with the snap ring.

Lubrication Hole

Snap Ring

Push the oil seal within 3.3

to 3.8 mm (0.13 to 0.15 in.)

from the crankcase surface.

Oil Seal

Bearing

Push the bearings until they

contact the snap ring.

Lubrication Hole

Crank Case

Construction

【

【【

【

Fan Side

】

】】

】

Push the oil seal

until its surface

comes trim with

the crankcase

edge surface.

Oil Seal

【

【【

【

Starter Side

】

】】

】

Push the oil seal until

its surface comes trim

with the crankcase

edge surface.

Bearing

Push the bearings until they

contact the snap ring.

Bearing

Push the bearings until they

contact the crankcase.

Snap Ring

Oil Seal

Crank Case

Construction