Page 4 of 28

802253NZ - HT BC Residential Instructions 10.18 v3.00

Before Installation:

A.

Read the instructions and check if there is adequate space to mount all of the components.

B.

Note: Not all fittings are supplied with the appliance kit. Isolation valves are not supplied.

C.

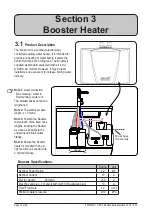

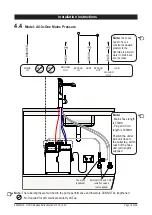

Check the mains water pressure is between 150 - 700kPa and 200 - 700kPa when a booster

and /or filter softener is fitted

D.

Check the water quality to determine if extra filtration will be required.

NOTE:

This product must be fitted to a potable water supply

E.

Check the appliance rating plate and ensure correct power is available for the appliance.

F.

Check the under counter cupboard supporting the appliance is adequate for the total weight

of the appliance, when full of water.

Before Commissioning:

1.

Check the unit has been installed correctly.

2.

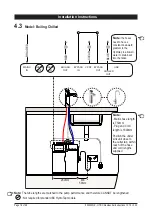

Check all plumbing fittings have been tightened.

3.

Ensure the outlet and vent pipes are positioned to drain correctly.

4.

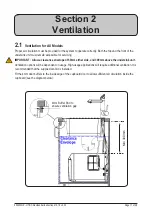

Ensure there is adequate ventilation.

5.

Check all tubes from the undersink unit to the tap, have a constant rise and there are no

sags or kinks in the hoses.

6.

Check all electrical connections are correct and there are no loose wires.

Commission: (see section 5)

7.

Flush the supply line before connecting.

8.

Turn on the water and check for leaks.

9.

Flush the filter(s).

10.

Where applicable, program the unit to suit the customer’s requirements.

Installation Checklist