Advertorial

Application Report

MATERIALS WORLD August 2009

41

Quantification of non-metallic

inclusions in steel

EN10247 – Challenges and opportunities

R

ecent years have shown a tremendous

increase in global steel production. In

2007 approximately 1,344 billion tons of steel

have been sold in the marketplace with new

manufacturers entering the market to meet the

growing demand. However the applications

still vary with respect to the properties of the

steel and range from standard construction to

use in technical high-end products (i.e.

Aerospace). It is within this last segment

where quality is crucial and minor impurities

or defects can cause failure to a component

under peak stress or even in routine

conditions. Consequently quality control in

production and the purchase of steel has

gained importance in high end applications as

the market offers a wider range of products

than in the past.

One of the basic quality issues in steel

production is "cleanliness". During the

manufacturing process different influencing vari-

ables may cause impurities within the product.

These predominantly non-metallic inclusions

may stem from covering slag on top of the cast

or cladding of the oven. Besides these

externally produced inclusions, internally

generated inclusions may occur through added

alloy elements or side reactions with

precipitating gases. These inclusions can

decrease the steel quality and determine the

field of application of the steel. Oxide inclusions

for example have a significant higher hardness

than the surrounding steel matrix. This could

lead to notch effects within a component under

stress conditions causing cracks and finally

failure. Non-metallic inclusions considerably

affect the mechanical properties of steel and

impact toughness and fatigue stress. Other

important properties such as ductility,

machinability, tribologic properties, surface

quality and physical properties may strongly

vary due to the inclusion content. Different

behavior in thermal expansion of the inclusion

and surrounding steel matrix for example may

lead to the creation of micro-voids initiating

cracks and failure.

To avoid failure of components in high-end

critical applications and to prevent associated

financial consequences due to legal claims an

optimum quality in the steel manufacturing

and processing industry must be met.

A new European standard EN10247 has been

released to cover quality assessment of steel not

only manually, but with the aid of an automated

microscope system using digital camera

technology and image analysis. The EN10247

aims to support high throughput analysis for

routine measurement of the inclusion content in

steel. The new European standard is based on

mathematical relations of inclusions favoring an

automated analysis over the time consuming and

possibly error prone manual inspection method.

Microscope manufacturers have been included in

the process of creating this new standard

providing system solutions as the EN10247

takes effect.

To adequately determine the quality of a

steel sample with an automated microscope,

such as the Axio Imager.Z2m from Carl Zeiss,

sample preparation needs to meet new

Go to www.iom3.org/marketplace

requirements. Samples with minor preparation

imperfections, to a certain extent, can still be

analyzed manually as the human eye remains

superior in detecting artifacts. As for

automated analysis the quality of preparation

is of major importance. The optimal planarity

of a micro section along with a surface free of

stains and scratches is decisive. Although the

state of the art software as the AxioVision

Module NMI provides sophisticated

algorithms to overcome insufficient planarity

and even excludes remaining scratches from

the evaluation, a proper sample preparation

remains irreplaceable. This guarantees

efficiency and cuts down laborious post

processing. Furthermore it provides highly

reproducible and stable results which can not

be matched by manual inspection.

The complete microscope system for

automated analysis of non-metallic inclusions

provided by Carl Zeiss consists of the

Axio Imager series microscope with excellent

optics and equipped with a digital camera, a

motorized stage, PC and software. The system

is designed for automatic scanning of a sample

area of 200 mm

2

, even for several samples, as

required in the EN10247. Within the AxioVision

software the module NMI provides a guided

workflow for user friendly operation in daily

routine. Optimized for a special requirement the

system is also suitable for many other

applications in a materials testing lab.

Volker Pusch

University of Aalen, Germany

Research Group Materials Engineering

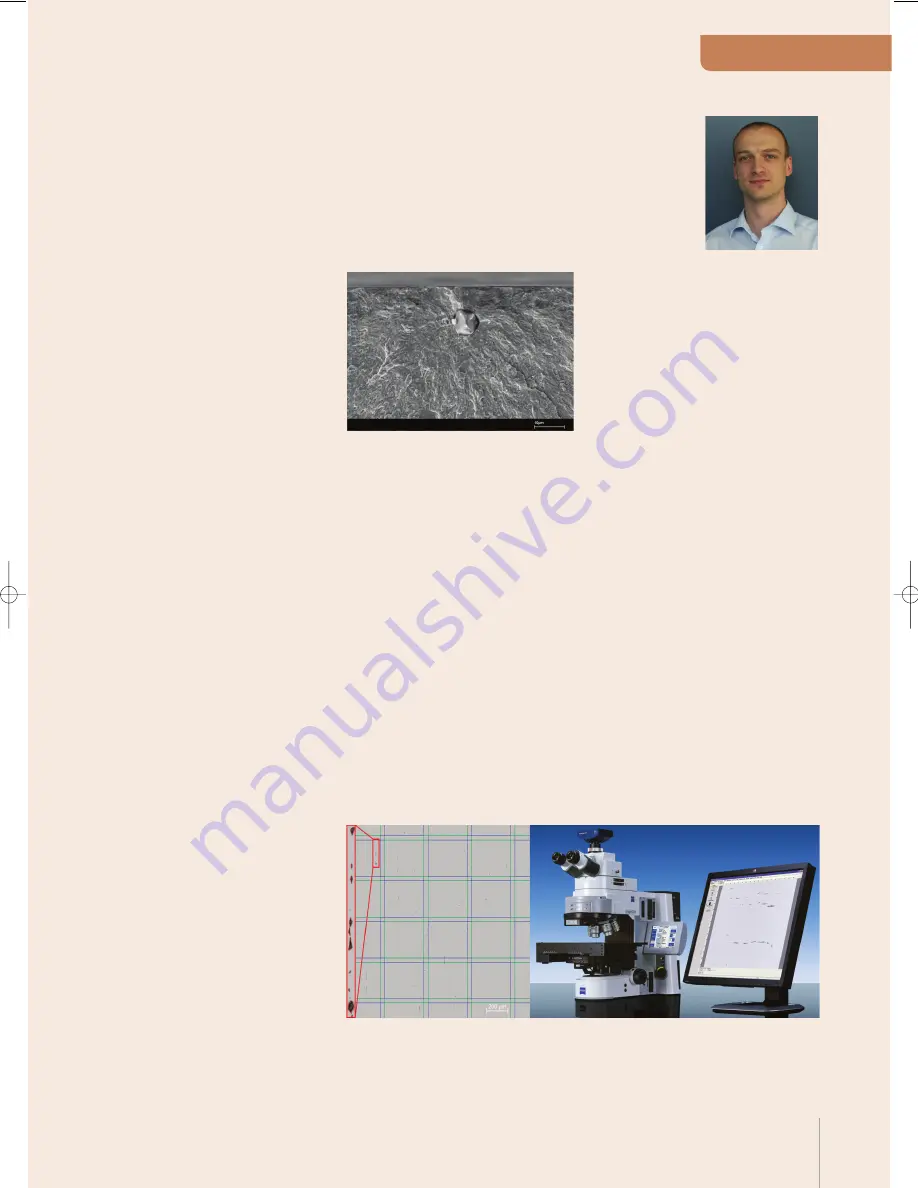

Scanning electron microscopic image of a 5µm

oxide inclusion as a failure initiating site.

The component failed due to a fatigue crack

which was originated at the top of the unwanted

feature in the microstructure within the (535A99)

100Cr6 matrix.

NMI measurement and System NMI. The left hand side shows a tile image of a processed measurement:

A critical line of oxide inclusions of 160µm in length (see magnified inset on the left) that has been both

automatically detected by the system and combined into one inclusion stringer according to the

standard. The right hand side shows a System NMI based on an Axio Imager.Z2m

profile Zeiss:Layout 1 16/7/09 08:11 Page 41