YZ Systems Milton Roy • 201 Ivyland Road • Ivyland, Pennsylvania • USA • 18974 • P: 281.362.6500 • www.yzsystems.com

Page 31

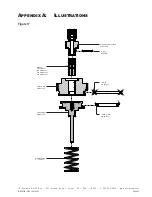

NJEX 610G / 610F ver.11-2023

Section 9: 610G / 610F System Troubleshooting

1. Verify operating conditions. Correct as

needed.

2. Check to see if the pump operation sounds

the same as previously. A distinct bottoming

of the plunger piston and a return to the top

of the plunger piston housing should be

audible with each actuation. If not, remove the

actuation cylinder. Inspect for a broken return

spring, or a stuck / sticking actuator piston or

plunger. Replace the spring if broken. Clean

and lubricate the actuation cylinder and

actuation piston assembly. Manually push the

plunger into the seal assembly and ensure it

returns completely and freely. If sticking

continues to occur, the seals should be

replaced. Reassemble and see if alarm

reoccurs after a system restart.

3. If pump actuation is normal:

a. Inspect the discharge lines and valves for

a restriction.

b. Inspect all the check valves on the

discharge side of the pump, from the

NJEX LVO System to the pipeline, for

proper operation.

c. Verify that the operating conditions

remain unchanged and correct as

needed.

4. Verify that the actuation pressure remains

unchanged from previous setting.

5. Verify that all valves and check valves are

properly set for system operation. Inspect for

valve settings that can restrict pump

displacement.

6. Check the actuation gas filter for flow

restriction or closure.

7. Ascertain whether the pump is properly

stroking.

Troubleshooting: Pump Performance

a. If pump actuation does not occur as the

test key is pressed, remove the actuation gas

line at the top of the pump and test the pump

stroke again. As the Test key is pressed, there

should be a burst of gas at the open actuation

supply connection. If the gas is released from

the open actuation supply line skip to

subsection 7.e., otherwise continue to 7.b.

b. If solenoid discharge to the pump

connection does not release gas, remove the

pump solenoid wiring cable. Next connect

a multimeter to the connections 10 and 11 on

the Z-100 controller. Press the test function on

the Z-100 by pressing up on the navigation

swtich while on the home screen or by the test

screen. Observe if an approximate 12VDC

current becomes present. If a voltage is detected

the solenoid should be replaced.

c. If the above test indicates the solenoid is

functioning, next determine if the signal is

being sent by the controller, or lost in the

cabling and connections. Go to the Z-100

Controller terminal strip and connect your

volt meter, to terminals 10 and 11, with 11

being the positive wire and 10 being the negative

wire. Now, test fire the pump with the test

function on the Z-100 by pressing up on the

navigation swtich while on the home screen

or by the test screen. A momentary voltage

pulse, approximately 0.2 seconds in duration,

should be observed. This will be a DC voltage

pulse, approximately 12VDC Varies based on

battery or external supply voltage. If the pulse

is at the termination strip, next check the

polarity of connections of the wiring. Try

reversing the terminal wiring connections for

the terminals 10 and 11, and repeat steps 7a

and 7b. If this does not correct the problem the

cable assembly to the solenoid should be replaced.

d. If no voltage is detected, check the fuses on the

circuit board using the label adhered to the

potting as a guide. Replace fuses as necessary.