YZ Systems, Inc. • 3101 Pollok Drive • Conroe, Texas • USA • 77303 • P: 936.788.5593 • F: 936.788.5720

Page 23

DP-2010FU ver.04202004

SSSSS

ECTION

ECTION

ECTION

ECTION

ECTION

77777::::: P

P

P

P

P

R

RR

R

ROGRAMMING

OGRAMMING

OGRAMMING

OGRAMMING

OGRAMMING

FOR

FOR

FOR

FOR

FOR

P

P

P

P

P

R

RR

R

ROPOR

OPOR

OPOR

OPOR

OPORTION

TION

TION

TION

TIONAL

AL

AL

AL

AL

-----

TTTTTO

O

O

O

O

-----TTTTT

IME

IME

IME

IME

IME

W

W

W

W

W

/DPS-2

/DPS-2

/DPS-2

/DPS-2

/DPS-2

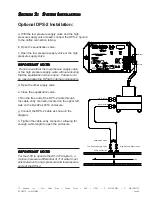

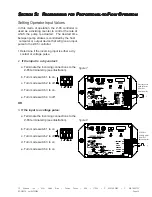

1. Calculate the sampling rate using the

following 30 day chart:

2. Set the timer dials on the Z-65 to the

determined time from step 9.1.

Example

12

.400

18

36

60

9

13

27

45

3

6

4

9

18

9

15

30

.300

.200

.100

Number of turns

open on pump

stroke knob

sample

pump

displacement

per stroke

1000 cc

500 cc

300 cc

Sample cylinder volumes

Sample

rate

(minutes)

18 minutes

3

2

0

9

6

8

7

1

3

2

5

4

0

9

1

6

7

8

5

4

IMPOR

IMPOR

IMPOR

IMPOR

IMPORTTTTTANT NO

ANT NO

ANT NO

ANT NO

ANT NOTE:

TE:

TE:

TE:

TE:

To obtain maximum battery life, choose the

longest time interval and the largest pump

displacement setting possible.

IMPOR

IMPOR

IMPOR

IMPOR

IMPORTTTTTANT NO

ANT NO

ANT NO

ANT NO

ANT NOTE:

TE:

TE:

TE:

TE:

The time (18 minutes) above corresponds to the

dial setting shown for the Z65 model with the

timer range setting in the factory position

(jumper on the two left pins).

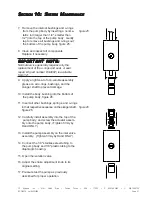

figure 14

figure 15