FORM 155.32-ICOM2.EN.UL

SECTION 7 – MAINTENANCE

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

123

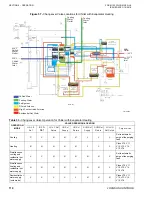

PURGE PROCEDURE

Air must be purged from the chiller-heater to maintain optimal performance and prevent

deterioration of internal parts. This chiller-heater has an automatic purge system.

Even if the automatic purge mode is used during normal operation, perform the manual

operation for the purging tank and absorber periodically. Purging period time tables must

be examined. See

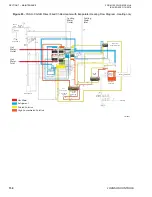

CAPACITY CHECK METHOD OF VACUUM PUMP

For commissioning and regular maintenance, check the capacity of the vacuum pump first

according to the following procedure.

1. Check the oil level in the vacuum pump.

2. If the oil is cloudy, it contains water and must be replaced with new oil.

3. Open the gas ballast (remove the plug).

4. Set the valves according to Pattern A. See

.

5. Press the Purge Model

Manual

button on the Setting screen.

6. Press the Manual Purge

ON

button. The vacuum pump starts. The solenoid valves

SV1 and SV2 open.

7. After another 1-2 minutes, confirm that the vacuum gauge stands at 0

~

1 kPa.

8. Press the Manual Purge

OFF

button. The vacuum pump stops.

9. Wait for 30 minutes.

10. Confirm that the vacuum down is within 2 kPa.

NOTE: See the Operation Manual for the Vacuum Pump for more information on how to

change the oil

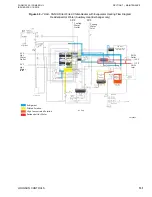

CAUTION: If the purge unit is operated with the gas ballast closed, water is left in the

oil. The oil will need to be replaced more frequently.