FORM 155.32-ICOM2.EN.UL

SECTION 2 - PRODUCT DESCRIPTION

ISSUE DATE:1/10/2018

JOHNSON CONTROLS

19

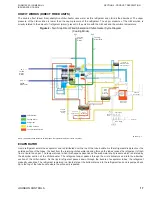

PLATE TYPE HEAT EXCHANGERS

The dilute (weak) LiBr solution leaving the absorber section is pumped through various

plate type heat exchangers (such as the low temperature heat exchanger, LTG refrigerant

condensate heat exchanger, and high temperature heat exchanger) before it enters the

high temperature generator and low temperature generator sections. These plate type heat

exchangers provide cycle efficiency by preheating the dilute solution. Preheating the dilute

solution reduces the consumption of the driving heat source in the high temperature

generator section. The concentrated solution flows out of the generators and back through

the heat exchangers.

The relatively high temperature solution streams from the two generators are used to pre-

heat the weak solution stream leaving the absorber.

PARALLEL FLOW

The unique parallel flow divides the solution between the low temperature generator and

the high temperature generator sections into two parallel, balanced paths. The result is a

safer and more efficient operation at a much lower pressure than conventional series-flow

designs. The various solution-to-solution plate type heat exchangers optimize efficiency by

enabling effective heat transfer between the diluted (weak) and the concentrated LiBr

solutions.

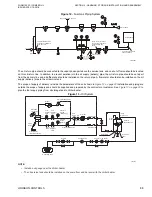

HIGH TEMPERATURE GENERATOR (HTG)

YHAU’s high temperature generator has the unique liquid tube design in which the dilute

LiBr solution coming from the high temperature heat exchanger is inside the tubes. The

products of combustion (exhaust gas from burning of natural gas) are on the shell side. The

hot refrigerant vapor boiled off is sent to the low temperature generator. This leaves behind

a strong solution which is returned through the high temperature heat exchanger.

The liquid tube design is efficient and compact with lower pressure drop as compared to

the conventional smoke tube type design in which the exhaust gas is inside the tubes while

the LiBr solution is on the shell side. Being more efficient, the exhaust gas leaving

temperature is lower than the smoke tube design.

The liquid tube design also benefits from less volume of LiBr solution and hence faster

startup time. It does not require any ceramic refractory compared to the conventional

design, therefore improved reliability.

LOW TEMPERATURE GENERATOR (LTG)

The hot refrigerant vapor from the high temperature generator heats up the dilute solution

coming in from the low temperature heat exchanger. This vapor then condenseses into hot

refrigerant liquid and is sent to the condenser via the drain heat exchanger. The additional

vapor produced in the LTG by heating up the dilute solution is sent to the condenser.

The LTG is of a falling film design, ensuring superior heat transfer and enhanced life by

eliminating wear and tear at the tube supports.

Concentrated

Solution In

Dilute

Solution In

Low Temp.

Heat Exchanger

)UTIKTZXGZKJ

9UR[ZOUT5[Z

*OR[ZK

9UR[ZOUT5[Z