JOHNSON CONTROLS

24

FORM 160.69-O2

ISSUE DATE: 9/30/2020

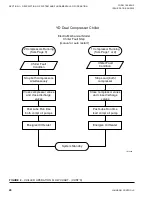

SECTION 2 – SYSTEM OPERATING PROCEDURES

START-UP

1. If the chilled water pump is manually operated,

start the pump. The Control Center will not al-

low the chiller to start unless chilled liquid flow

is established through the unit. (A field supplied

chilled water flow switch is required.) If the

chilled liquid pump is wired to the Microcom-

puter Control Center the pump will automatically

start, therefore, this step is not necessary.

2. To start the chiller, press the

COMPRESSOR

START

switch. This switch will automatically

spring return to the RUN position. (If the unit

was previously started, press the

STOP/RESET

side of the

COMPRESSOR

switch and then

press the

START

side of the switch to start the

chiller.) When the start switch is energized, the

Control Center is placed in an operating mode and

any malfunction will be noted by messages on a

graphic display.

Any malfunctions which occur during

STOP/RESET are also displayed.

When the chiller is shut down, the prerotation vanes

will close automatically to prevent loading the com-

pressor on start-up.

When the chiller starts to operate, the following auto-

matic sequences are initiated:

1. The OptiView™ Control Center display message

will read

SYSTEM PRELUBE

for the first 50

seconds of the starting sequence.

2. The oil pump will start to circulate oil for a

50 second pre-run to establish oil flow and

adequate lubrication to all bearings, gears,

and rotating surfaces within the compressor.

The high and low oil pressure transducers (OP)

and the oil temperature sensor (RT3) will sense

any malfunction in the lubrication system.

3. The anti-recycle timer (non-VSD Chillers only)

software function will operate after the 50 sec-

onds of pre-run time. At this time, the timer will

be initiated and will run for 30 minutes after the

compressor starts. If the chiller shuts down during

this period of time, it cannot be started until the

timer completes the 30 minute cycle.

4. The chilled liquid pump contacts will close, start-

ing the chilled liquid pump, to allow liquid flow

through the evaporator when the COMPRESSOR

start switch is energized.

5.

After the first 50 seconds of operation, the com

-

pressor will start.

6. For display messages and information pertaining

to the operation of the OptiView™ Control Cen-

ter,

refer to Form 160.69-O1

.

CHILLER OPERATION

After the compressor reaches its operating speed, the

Prerotation Vanes will begin to open under the control

of the Microprocessor Board which senses the leav-

ing chilled liquid temperature. The unit capacity will

vary to maintain the leaving

CHILLED LIQUID

TEMPERATURE

setpoint. The Prerotation Vanes are

modulated by an actuator under the control of the Mi-

croprocessor Board. The vane control routine employs

proportional plus derivative (rate) control action. A

drop in chilled liquid temperature will cause the actua-

tor to close the Prerotation Vanes to decrease chiller

capacity. When the chilled liquid temperature rises, the

actuator will open the Prerotation Vanes to increase the

capacity of the chiller.

However, the current draw (amperes) by the compres-

sor motor cannot exceed the setting of the

% CUR-

RENT LIMIT

at any time during the unit operation,

since the Microcomputer Control Center 40 to 100%

three-phase peak current limit software function, plus

the 3-phase 100% solid state overload current limiter

(CM-2), on Electro-Mechanical Starter applications, or

the Solid State Starter current Limit function will over-

ride the temperature control function and prevent the

Prerotation Vanes from opening beyond the

% CUR-

RENT LIMIT

setting.

If the load continues to decrease, after the Prerotation

Vanes are entirely closed, the chiller will be shut down

by the Leaving Chilled Liquid – Low Temperature

Control.

Summary of Contents for YD A

Page 8: ...JOHNSON CONTROLS 8 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 22: ...JOHNSON CONTROLS 22 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 28: ...JOHNSON CONTROLS 28 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 34: ...JOHNSON CONTROLS 34 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 48: ...JOHNSON CONTROLS 48 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...