YORK INTERNATIONAL

7

FORM 155.16-O3

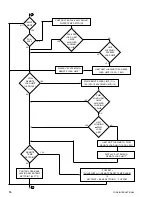

manual operation of the refrigerant level solenoid is only

allowed in MANUAL PUMPS key via the special access

code in the PROGRAM MODE. If the refrigerant level

solenoid is manually energized (open), it is de-energized

(closed) as follows:

• Manually, using the DISPLAY DATA key

• Automatically, if the mode is changed for SERVICE to

LOCAL or REMOTE

Whenever the refrigerant level float switch is open, the

dilution cycle is inhibited or terminated.

Whenever the panel is placed in MANUAL SOLENOID

OPERATION in SERVICE mode through the use of the

MANUAL PUMPS key via the special access code in

PROGRAM mode, both the refrigerant solenoid valve

and the stabilizer refrigerant solenoid valve fall under

manual control. With the exception of the automatic

decrystallization routine, neither pump will respond to

any automatic control while manual control is active. If

the automatic decrystallization routine become active,

the refrigerant stabilizer solenoid valve is reverted from

manual control back to automatic control for as long as

the decrystallization, routine is active. At the end of the

automatic decrystallization, the refrigerant stabilizer so-

lenoid, if previously in MANUAL mode, will once again

fall under manual operation. When automatic solenoid

operation is selected using the same procedure de-

scribed above, manual control of the refrigerant level

solenoid valve is inhibited and only automatic controls

will affect the operation of the valves. Upon exit form

SERVICE mode, if the valves are in MANUAL OPERA-

TION mode, they will automatically switch to automatic

solenoid control operation.

When the unit is running, there are two different fea-

tures designed to prevent crystallization; if unit is

equipped with EPROM version A.02F.00, the STRONG

SOLUTION TEMP CONTROL is used. If the unit is

equipped with EPROM version A.02F.01 or later, this is

replaced by “LOW ENTERING CONDENSER WATER

TEMP LOAD LIMIT”.

When the unit is equipped with EPROM version A.02F.00,

three temperatures are monitored to perform STRONG

SOLUTION TEMP CONTROL as follows:

• Refrigerant Temperature Leaving the Condenser

(RTLC)

• Strong Solution Temperature

• Leaving Chilled Water Temperature (LCWT)

The first two sensor temperatures are displayed via the

REFRIGERANT / SOL’N TEMPS keys using a scrolling

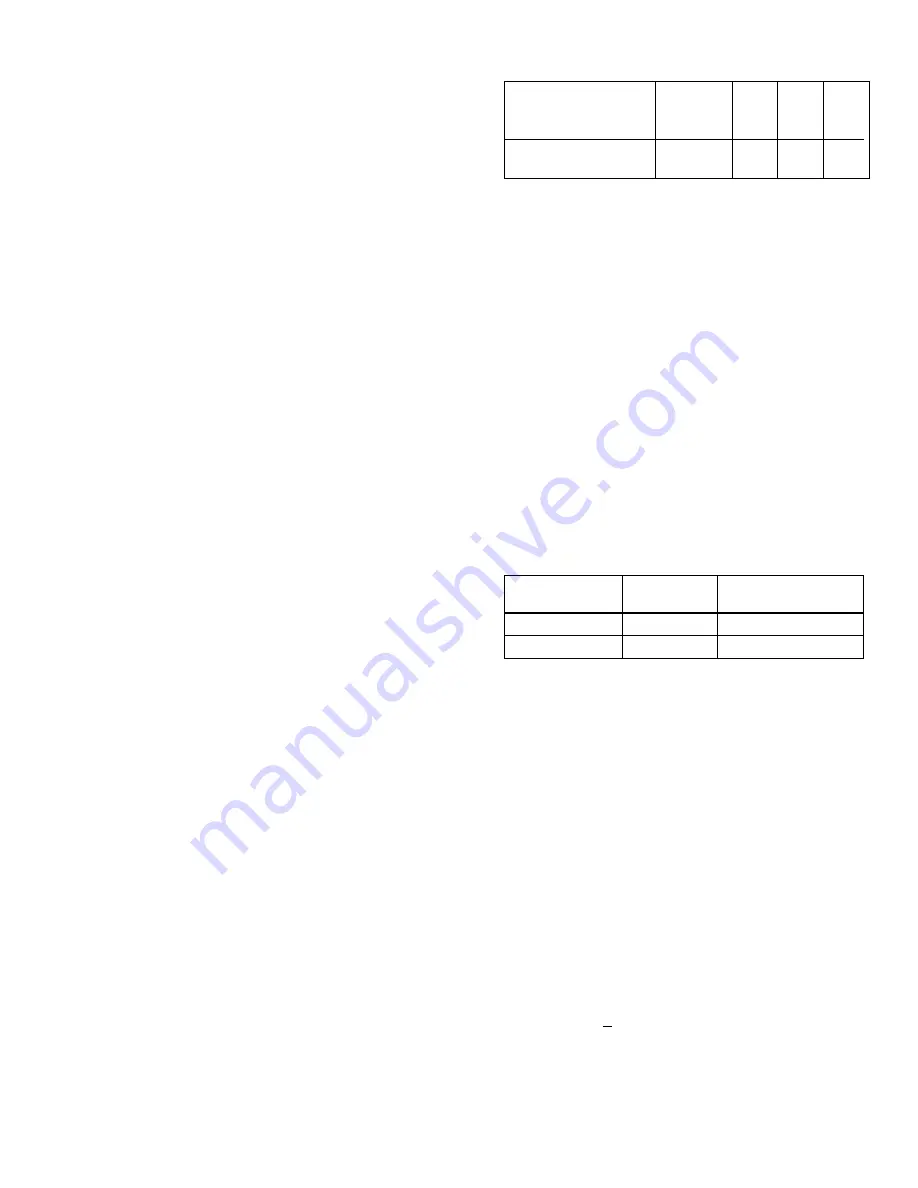

technique. Whenever the RTLC is between 72°F and

117°F (22.2°C and 47.2°C), the strong solution tempera-

ture shall not exceed the values listed following:

For RTLC values between 72°F and 117°F (22.2°C and

47.2°C), but not listed in the table, the corresponding

maximum strong solution temperature is interpolated. If

the strong solution temperature exceeds the allowable

limit, steam or hot water control valve loading is inhib-

ited and the RTLC/strong solution temperature algorithm

is enabled to slowly pulse the valve closed (based on

the table below) until the strong solution temperature is

less than or equal to the limit. However, if the leaving

chilled water temperature is less than or equal to the

setpoint, the steam or hot water control valve is closed

in accordance with the LCWT automatic temperature

control algorithm. Whenever the RTLC limits loading, the

displayed message is “SYSTEM RUN - STRONG SO-

LUTION TEMP CONTROL”. When the RTLC limits load-

ing, if subsequently the RTLC check determines that the

specified temperature is 1.0°F (.6°C) below the maxi-

mum, the message is replaced with “SYSTEM RUN -

LVG CHILLED WATER CONTROL”, and the automatic

temperature control algorithm is in effect.

If the unit is equipped with EPROM version A.02F.01,

the STRONG SOLUTION TEMP CONTROL is replaced

by LOW ENTERING CONDENSER WATER TEMP

LOAD LIMIT. After a 30 minute bypass at unit start, when-

ever the entering condenser water temperature is < 74°F

(23.2°C), the maximum allowed steam/hot water valve

position is determined by the valve profile. This profile

includes the valve size, flow characteristics and linear-

ity. These parameters are stored in memory and ac-

cessed based on the YORK part number of the value

used on the unit. This part number is entered by a quali-

fied serviced technician using a procedure in the “Ser-

vice” manual, Form 155.16-M3. While the loading is be-

ing limited due to this condition, “SYSTEM RUN - LOW

ECDWT LIMIT IN EFFECT” is displayed. Units equipped

with EPROM version A.02F.02 and later, in addition to

requiring the entering condenser water temperature to

be <74°F (23.2°C), also require the strong solution tem-

perature to be > the LOW ECDWT SOLUTION TEMP

OVERRIDE setpoint to perform this load limit. This

setpoint is entered by a qualified service technician us-

ing a procedure in “Service” manual, Form 155.16-M3.

An upper limit on entering condenser water tempera-

VALVE

PULSE

INTERVAL

TYPE

DURATION

BETWEEN PULSES

BUTTERFLY

1 second

15 seconds

CAGE/GLOBE

2 seconds

60 seconds

Maximum Refrigerant

Temperature Leaving

(°F)

72

97

104

117

the Condenser (RTLC) (°C) 22.2

36.1

40

47.2

Strong Solution

(°F)

170

205

214

231

Temperature

(°C) 76.7

96.1

101.1 110.6

Summary of Contents for MILLENNIUM YIA-HW-14F3

Page 116: ...YORK INTERNATIONAL 115 FORM 155 16 O3 NOTES...

Page 117: ...116 YORK INTERNATIONAL NOTES...