9-20

IM 04P02B01-01E

9.12 Setting the Timer Used in TLOG Computation

and Periodic Printout

This section explains the details of setting the timer used in TLOG computation and

periodic printout.

Basic Setting mode cannot be entered when recording is in progress or when

computation is in progress on models with the computation function (/M1 option).

Procedure

Changing the Settings

1.

Hold down the

MENU

key for 3 seconds to enter Setting mode.

2.

Hold down the

and

keys simultaneously for 3 seconds to enter Basic

Setting mode.

3.

Press the

key or

SHIFT

+

key to select

Math

and then press the

key.

4.

Press the

key with

Timer (TLOG)

shown on the screen.

5.

Set each item and press the

key.

Use the

key or

SHIFT

+

key to select values.

For the procedure on how to enter values or characters, see section 4.2.

If you press the

ESC

key in the middle of the operation, the settings entered up

to then are cancelled, and the display returns to a higher level menu.

6.

When the

Setting complete

screen appears, do either of the following:

To correct the setting, press the

key.

If you are done, press the

ESC

key.

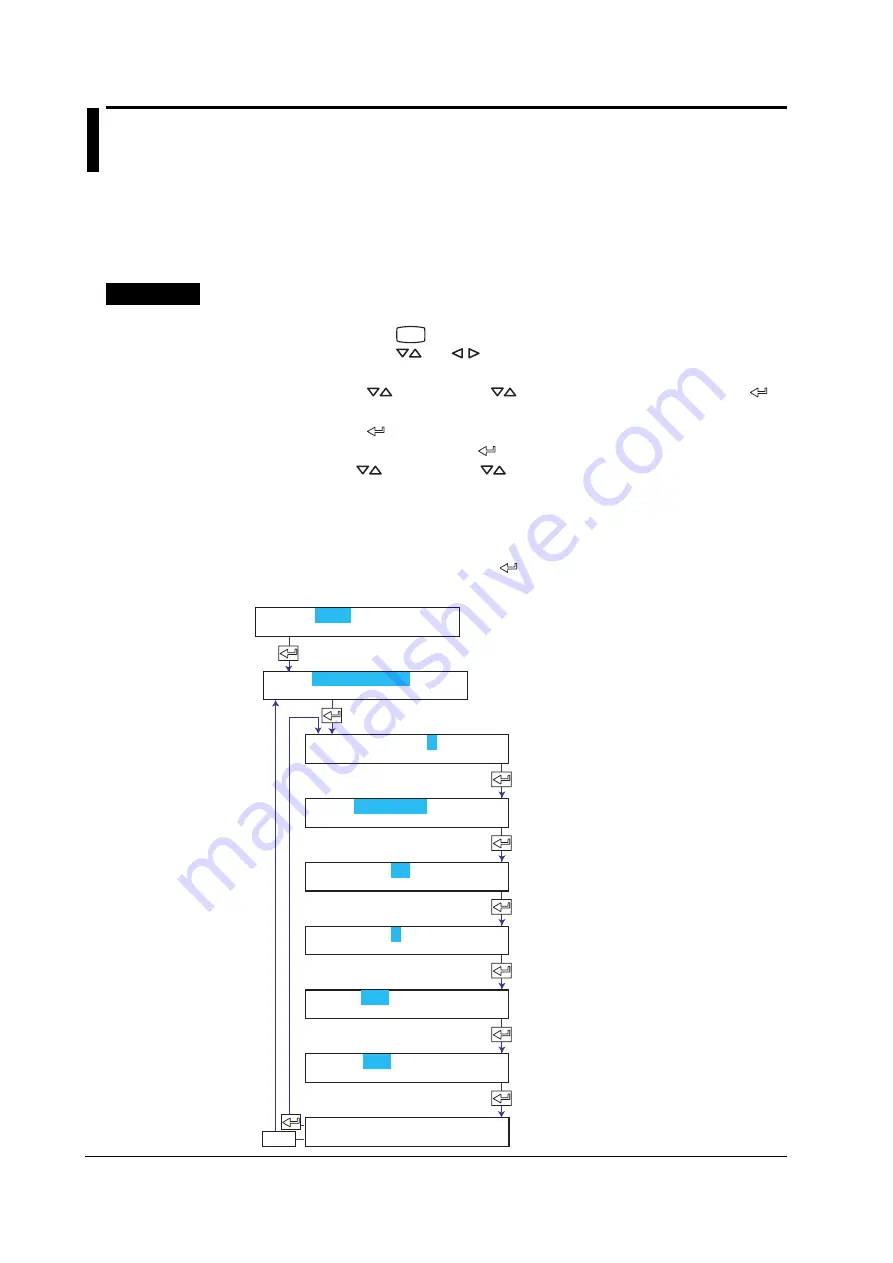

Select the timer No.

The new setting takes effect.

ESC/?

Select the timer type.

(When the mode is set to Absolute)

(When the mode is set to Absolute)

Select the timer interval.

Set the reference time.

Select On to reset the computed

values every interval.

Select On to print the computed

values every interval.

Math Timer

Setting complete

Basic=Math

Math=Timer(TLOG)

Timer number=1

Mode=Absolute

Interval=1h

Ref.Time=00:00

Reset=Off

Print=Off