<8. Detailed Description>

152

TI 34P02K35-02E Jun. 6, 2018-00

8.4.4 Selecting between SFC and Stepped FBD or LD

● Characteristics of SFC Programming Language

The SFC is a step execution type of language, which processes one step after

another, and is thus ideal for building process progress type applications and

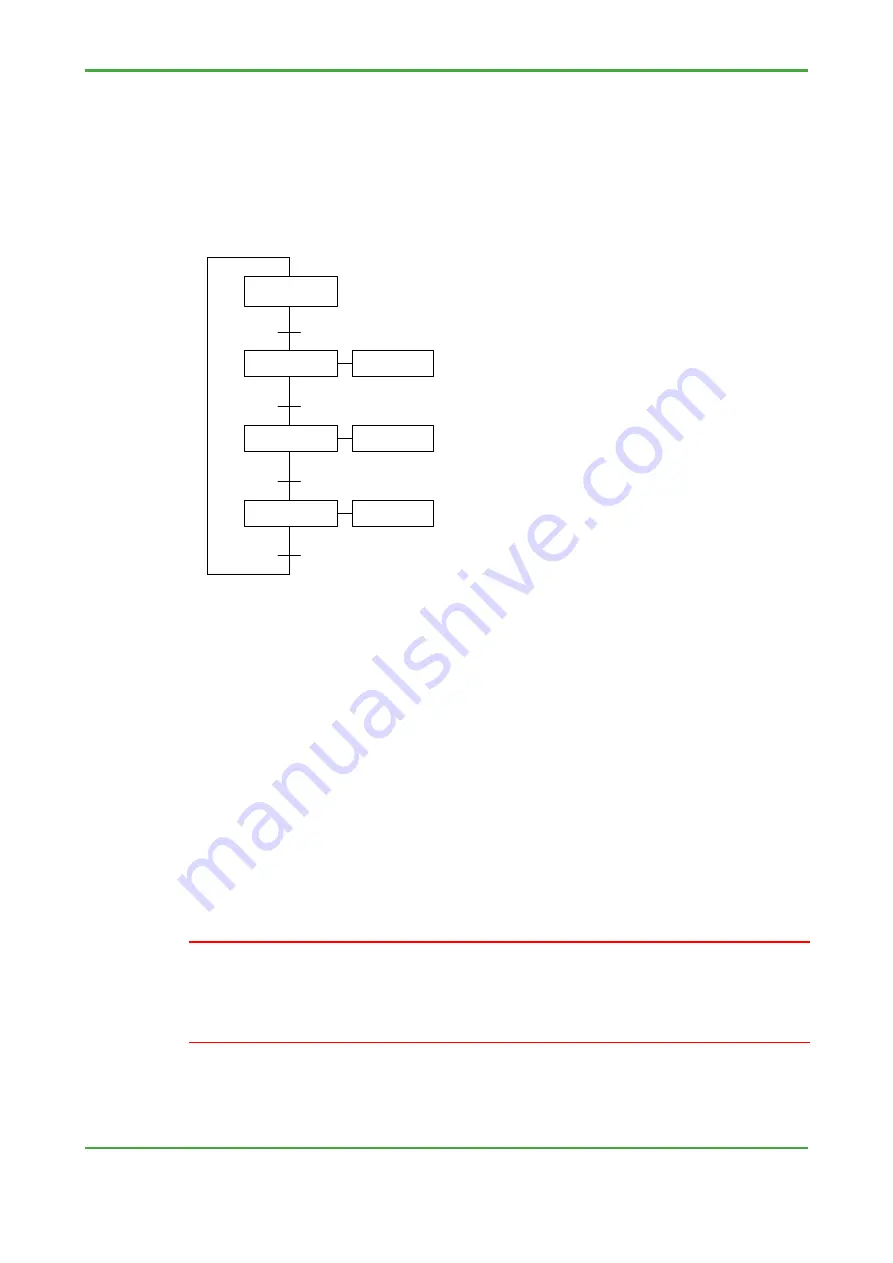

sequence control applications. The figure below shows a schematic of an SFC

application.

STEP0

STEP1

ACTION1

STEP2

ACTION2

STEP3

ACTION3

TRANSITION1

TRANSITION2

TRANSITION3

TRANSITION4

In the application shown in the above picture, while the SFC process is at initial step

STEP0 and the process transition condition TRANSITION1 becomes true, the

process moves to STEP1 and ACTION1 is executed.

While the process is at STEP1 and TRANSITION2 becomes true, the process

moves to STEP2 and ACTION3 is executed.

Similarly, while the process is at STEP2 and TRANSITION3 becomes true, the

process moves to STEP3 and ACTION3 is executed.

While the process is at STEP3 and TRANSITION4 becomes true, the process

moves to initial step STEP0.

In this way, processing in SFC progresses one step at a time so SFC is well suited

for building process progress type applications and sequence control applications.

Moreover, actions of ACTION 1, ACTION 2 and ACTION3 can be coded in FBD, LD,

IL or ST language.

IMPORTANT

For ease of explanation, a simple description of actions of ACTION1, ACTION2 and

ACTION3 is shown in the above figure; the actual operation of SFC is a little more

complex.

For details, see Logic Designer’s online help documentation.

Summary of Contents for STARDOM FCN-500

Page 2: ...Blank Page...

Page 10: ...Blank Page...

Page 32: ...Blank Page...

Page 36: ...TI 34P02K35 02E Jun 6 2018 00 Blank Page...

Page 76: ...TI 34P02K35 02E Jun 6 2018 00 Blank Page...

Page 163: ...Blank Page...

Page 221: ...Blank Page...

Page 225: ...Blank Page...