IM 1E10C1-E

5-11

5. FUNCTION AND DATA SETTINGS

5.5.4

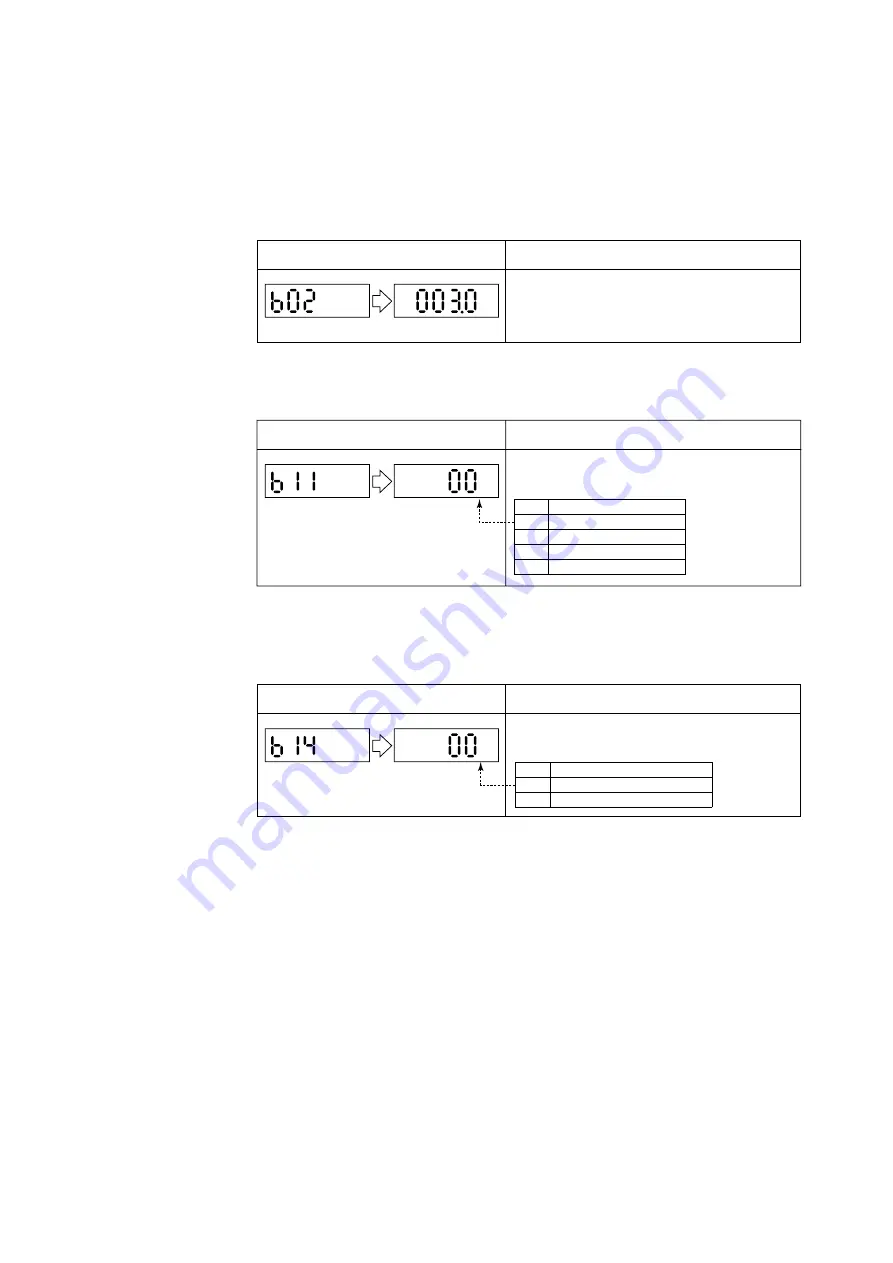

Damping Time Constant

• The time constant can be changed by setting the parameter No. “b02” to suppress a

fluctuation or change a response time.

• The time constant influences to flow rate, pulse output and internal totalization.

However, in case “00” is selected in parameter No. “n01”, the pulse output and

internal totalization are not influenced by it.

The time constant can be set in parameter No. “02”.

Setting Range: 0.5 to 200.0 sec.

Display

Description

Default: 3(sec).

5.5.5

Current Output during Alarm Occurrence

• The current output and display values during alarming can be selected in advance.

The current output value during alarming can be set in

parameter No. “b11”.

Display

Description

Code

00

01

02

03

2.4mA or less

4.0mA

HOLD

21.6mA or more

Default: 03

Content

5.5.6

Reversing Flow Direction

• The flow direction is set to “FORWARD” at the factory. This function enables to set

flow direction from “FORWARD” to “REVERSE”.

Display

Description

Code

00

01

Forward direction

Reverse direction to flow arrow

Content

The flow derection can be set in parameter No. “b14”.

Default: 00