INSTRUCTION 9000 – MODU-CAB

1

1/31/07

SUBMERSIBLE PUMPS

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

YEOMANS SERIES 9100 SUBMERSIBLE PUMPS

WITH SINGLE RAIL QUICK LIFT OR

DUAL RAIL EASY-LIFT

®

GUIDE RAIL SYSTEM

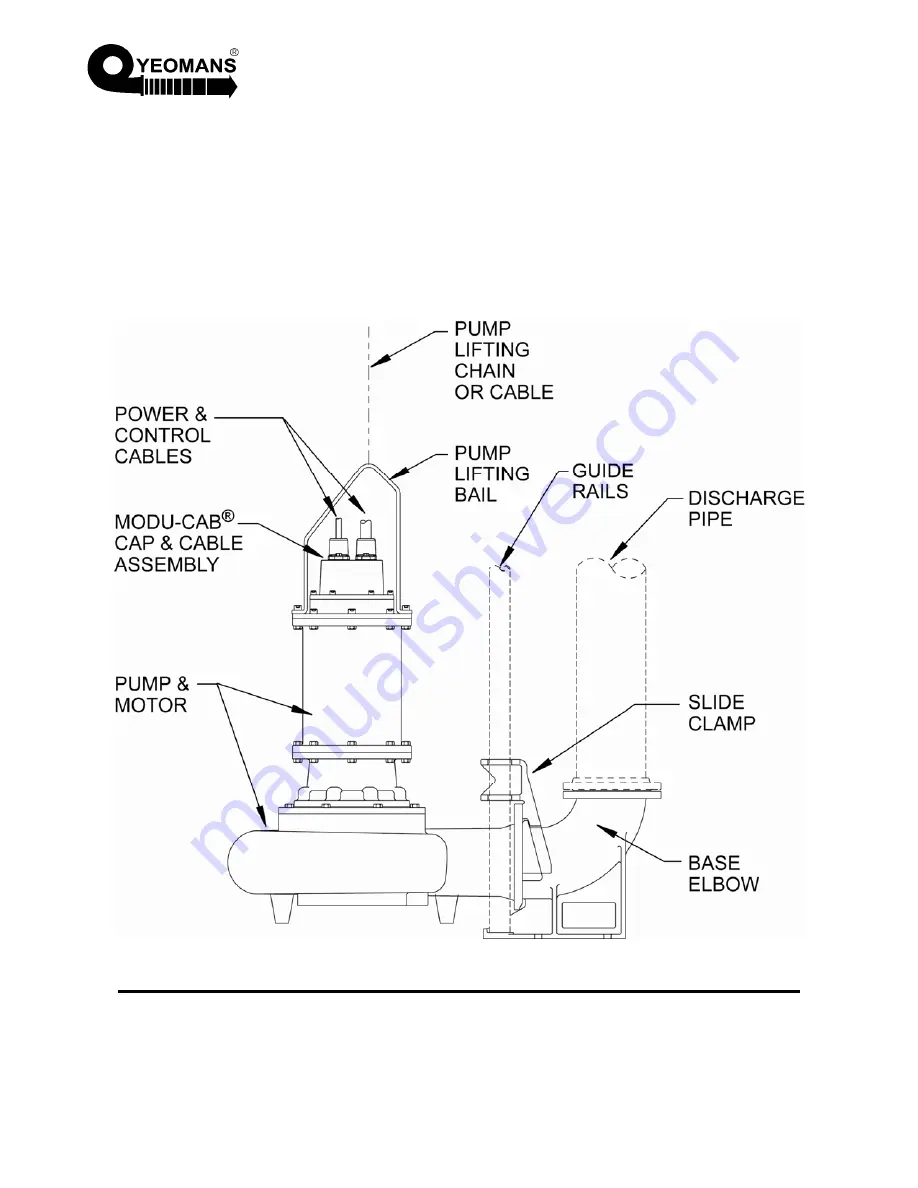

TYPICAL PUMP INSTALLATION

YEOMANS PUMP

3905 ENTERPRISE COURT

AURORA, IL 60504 USA