4.5 Start-Up Procedure

Follow the steps and procedures outlined below to help ensure proper start-up of the Z1000 Bypass.

u

Bypass Start-Up Preparation

1.

Remove power to the Z1000 Bypass and verify using a multimeter. Follow all appropriate lockout/tagout procedures.

WARNING! Electrical Shock Hazard. Do not remove covers or touch circuit boards while the power is on. Failure to comply could

result in death or serious injury.

2.

Record the motor nameplate information and verify that the input voltage matches the Z1000 Bypass rating. Verify

that the motor rated FLA does not exceed the rated output rating of the bypass unit, and verify that the motor FLA

falls in the rated range of the thermal overload relay (if present).

3.

Determine which type of main input disconnect is provided on the Z1000 Bypass.

The standard Z1000 Bypass includes a non-fusible disconnect switch that does not provide branch circuit protection.

Branch circuit protection is required to be installed according to applicable local codes and the requirements listed on

the Z1000 Bypass nameplate. Yaskawa recommends semiconductor fusing to ensure to 100 kAIC SCCR panel rating

and is specified on the nameplate of the Z1000 Bypass.

WARNING! Fire Hazard. Branch Circuit protection is required to be installed according to applicable local codes and the

requirements listed on the Z1000 Bypass nameplate. Failure to comply could result in fire and damage to the bypass and drive or

injury to personnel. The Z1000 Bypass is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical

amperes, 208 Vac and 480 Vac with the circuit breaker option or when protected by class J or class L fuses as specified on the

Z1000 Bypass nameplate. Consult factory with questions.

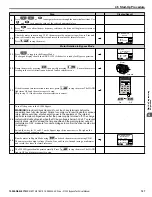

The Z1000 Bypass Option M provides an input circuit breaker. If provided, the adjustable trip level must be set using

the two dials located on the circuit breaker. The dial marked “FLA” sets the breaker to match the motor FLA. Use a

small straight-edge screwdriver and adjust to the appropriate current level. The other dial sets the inrush level. Make

sure this dial is set to “Auto 1” (factory setting).

4.

Verify that three-phase line power is connected to input disconnect device.

5.

Verify that the grounding terminal of the Z1000 Bypass is attached to the appropriate building ground circuit.

6.

Verify that wiring connections are properly terminated and connected to appropriate circuits at PCB A2 using the

Refer to Standard Connection Diagram on page 52

Please note the following in regards to the safety circuit (DI-2, terminal TB2-2) and the BAS interlock circuit (DI-3,

terminal TB3-3):

Safety Interlock Circuit

DI-2 (terminal TB2-2) is provided to connect safety devices in a normally-closed series circuit, such as: freeze up

thermostats, smoke/fire sensors, high pressure limits, temperature limits, or vibration detectors.

The HOA keypad will display a Safety Open fault if a N.C. safety circuit is not closed between DI-2 (TB2-2) and IG24

(TB2-10) on PCB A2 at power-up with a Run command in HAND or AUTO mode. An open circuit between DI-2 (TB2-2)

and IG24 (TB2-10) will prevent bypass operation.

Take one of the following steps to ensure proper operation prior to startup:

Install a N.C. safety circuit between DI-2 (TB2-2) and IG24 (TB2-10) on PCB A2.

Install a jumper between DI-2 (TB2-2) and IG24 (TB2-10) on PCB A2.

Building Automation System Interlock Circuit (Drive and Bypass Enable Input)

The HOA keypad will display “INTRLOCK OPN” to indicate a BAS Interlock fault is a N.C. safety circuit is not closed

between DI-3 (TB2-3) and IG24 (TB2-10) on PCB A2 at power-up with a Run command in HAND or AUTO mode. An

open circuit between DI-3 (TB2-3) and IG24 (TB2-10) will prevent bypass operation.

This condition is a fault and will prevent drive and bypass operation.

Take one of the following steps to ensure proper operation prior to startup:

Install a N.C. BAS Interlock Circuit/Damper Interlock between DI-3 (TB2-3) and IG24 (TB2-10) on PCB A2.

Install a jumper between DI-3 (TB2-3) and IG24 (TB2-10) on PCB A2.

7.

Verify that the motor is wired for the application voltage if it is a dual voltage motor.

8.

Connect the motor to the output terminals of the motor overload.

9.

Set the motor overload for the proper FLA of the motor.

10.

Verify that the motor ground is connected to the Z1000 Bypass drive ground terminal.

4.5 Start-Up Procedure

104

YASKAWA ELECTRIC SIEP YAIZ1B 01E YASKAWA AC Drive – Z1000 Bypass Technical Manual