4-13

162068-1CD

162068-1CD

MH-SERIES

POSITIONER

4 Installation

4.4 Tailstock Column Installation

5. To find the

X value

in the tailstock mounting formula for the drive

assembly, locate the drive assembly model name in

4.4.2

Type II Installation

To install the tailstock of a Type II assembly onto a cell base or floor,

proceed as follows:

1. Ensure the proper position for the headstock assembly per system

layout. The headstock must permanently anchored to the floor/base.

2. Using a carpenter’s chalk string, strike a chalk line on the floor from

the edge of the headstock base towards location of the tailstock.

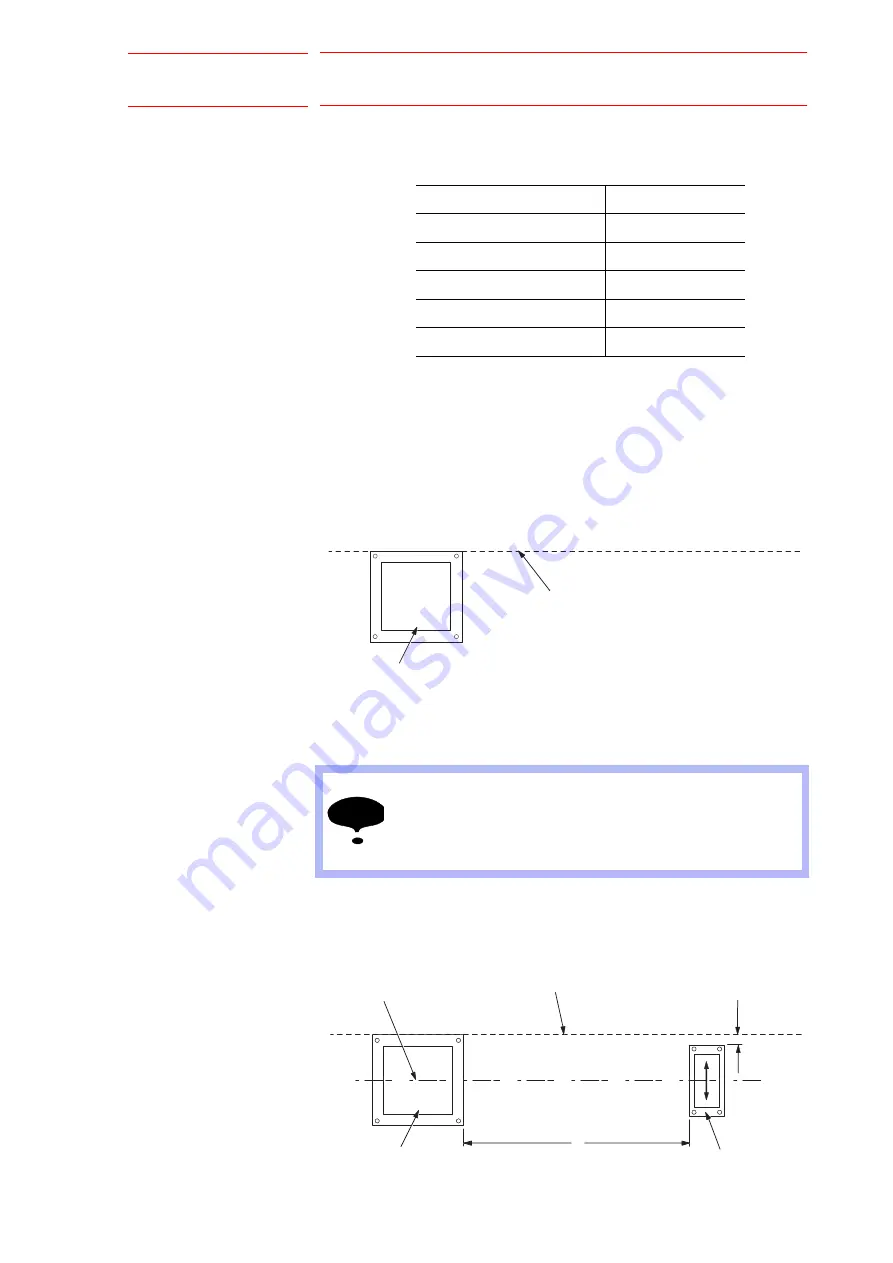

Fig. 4-22: Strike Chalk Line

3. Position the tailstock on the floor across from the headstock.

4. Use the chalk line and the center line of each component as guides for

placement of the tailstock column on the floor.

5. To position the tailstock accurately on the bearing center line, make

two measurements from the tailstock base to the chalk line and adjust

the base as necessary.

Fig. 4-23: Tailstock Placement - Type II

Table 4-6: MotoMount Offset (X Value)

Type I System

X - value

MHT95 - mm

8

MHT180 - mm

8

MHT505 - mm

57

MHT1605 - mm

168

MHT3105 - mm

145

NOTE

Keeping the center line of each component aligned is not

critical. However, the closer the bearings of both

components are aligned with one another, the greater the

degree of misalignment allowed with other system

components.

CHALKLINE

HEADSTOCK

COLUMN BASE

CHALK LINE

225 MM

(8.85 IN.)

TAILSTOCK

RISER BASE

D

HEADSTOCK/TAILSTOCK

BEARING CENTERLINE

39/101