12

6. Align and screw the collar onto the thread of the suction inlet (8) port of the

pump (Fig. 5).

Note:

Ensure the collar is tightly fastened onto the suction inlet (8); failure to do so

may result in an air leak.

Discharge Outlet

Connecting Hose or Pipe to the Discharge outlet (not included)

Note:

Keep all hoses short and as straight as possible, failure to do so may decrease the pumps performance.

Caution:

All connections must be air tight, failure to do so may result in an air leak which can prevent the pump

from priming. It is recommended that a thread sealant (not included) and/or Teflon tape (not included) is used on

threads to ensure a water tight seal and prevent any leakage.

1. Insert a hose adapter (24) into one of the collars (22).

Note:

Ensure that an o-ring (21) is fitted into the collar (22) (Fig. 6), failure to do so

may result in an air leak.

2. Add thread sealant (not included) and/or Teflon tape (not included) on to the

discharge outlet (9).

3. Align and screw the collar onto the thread of the discharge outlet (9) port of the

pump (Fig. 7).

Note:

Ensure the collar is tightly fastened onto the discharge outlet (9); failure to do so

may result in an air leak.

Priming

Priming the pump prepares the motor for safe operation.

Caution:

Do not run the pump dry, this may result in damage to the pump.

1. Unscrew the priming cap (11) by turning anti-clockwise. Using a hose, fill the pump

by pouring water into the priming plug hole (Fig. 8).

2. Ensure that the pump and suction line are full.

3. Replace the priming cap (11) and ensure it is secure.

4. Fully open any shut off mechanisms (eg: spray nozzle, valves etc.) in the input and output hose or pipe so that

the air can escape without obstruction.

SETUP & INSTALLATION (cont.)

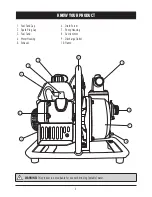

Fig. 5

Fig. 7

Fig. 8

Fig. 6

Summary of Contents for YW20PTP

Page 1: ...2 Stroke Petrol Transfer Pump Model YW20PTP 1013...

Page 3: ...3...