16 | RMB/ENERGIE GmbH

assembly

Operation manual CHP 5.0 - 30.0 | Status 01.2020

5.2.3 Heating system

The structural elements of the building’s heating

system primarily comprise the peak load boiler, the

buffer tank, and the pipework system and radiators.

The peak load boiler supplies the required residual

heat if the heating energy requirement exceeds the

capacity of the system (e.g. in extremely cold weather).

For the system to operate, a buffer tank is required,

which must comply with the following requirements:

B

The buffer tank must have holding fixtures for the

temperature sensors.

B

The buffer tank must have shut-off devices fitted on

the connections to the system.

B

The buffer tank must be designed to meet the

system specifications.

B

Minimum 100 litres per kW thermal

for installations < 10 kW

th

B

Minimum 50 litres per kW thermal

for installations > 10 kW

th

These specifications are technical minimum conditions.

Regional or national funding guidelines (e.g. in

accordance with BAFA in Germany) may differ and

must be checked.

The dimensioning of the pipework system must be

designed to meet the following requirements:

B

Maximum heat requirement of the building.

B

Maximum thermal capacity of the system.

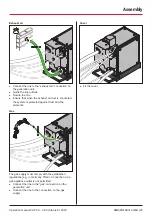

5.2.4 Flue gas routing

For the system to operate, the building must

have a flue, which must comply with the following

requirements:

B

The local laws and regulations must be complied

with (e.g. in Germany, the building regulations).

B

The flue gas routing must comply with the local

regulations (e.g. in Germany, DIN 18160).

B

The flue gases must be removed via a flue.

B

As a fundamental rule, the flue must extract the flue

gases via the roof.

B

The dimensions for the exhaust gas ducting and

flue must be calculated on an individual basis.

B

The gradient of the horizontal section must be min.

5 cm per metre.

B

The flue must be inspected and approved for

operation (e.g. by a master chimney sweep).

B

A flue gas silencer must be fitted in the flue gas

routing. The flue gas silencer (optionally available)

must be installed near the generation unit.

B

The flue gas routing must have a water-filled siphon

at its lowest point.

5.2.5 Exhaust air duct

D

WARNING!

Risk of suffocation due to improper use of exhaust

air!

The exhaust air must not be used for heating purposes.

Poisonous gases may be produced inside the

generation unit that can lead to death by suffocation.

A

Ensure that the exhaust air from the generation unit

is guided outside.

A

Ensure that the supply air is not contaminated by

the exhaust air.

An accessory is required (optionally available) if

exhaust air and flue gas are extracted together:

B

Exhaust air kit if extracting from one system.

B

Backflow preventer if extracting in combination with

another heat source (peak load boiler or another

system).

Additional devices with exhaust air (e.g. washer-dryers)

may only be installed subject to consultation with a

suitable specialist or chimney sweep.

5.2.6 Supply air supply

Sufficient supply air must be supplied for the

combustion process and the ambient temperature:

B

The total requirement of the heating system (e.g. for

the peak load boiler) must be born in mind.

B

The supply air supply must meet the system

specification.

Technical data.

B

The supply air must not be supplied via a concentric

pipe if the inner pipe is used for flue gas routing.

B

If the ambient temperature in the installation room is

permanently above 30 °C, additional air exchange is

required.