3. Troubleshooting

53

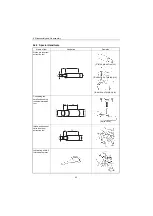

3.3 Troubleshooting (Concerning engine and fuel injection

equipment)

Malfunctions

Causes

Remedies

The engine does not operate

1. Fuel Oil is not injected from the

injection pump

1. There is no fuel oil in the fuel

tank

2. The fuel line from the fuel tank

is blocked

3. The fuel is clogged

4. There is air in the fuel filter or

the pump chamber

5. The accelerator linkage is not

properly connected

6. The magnet valve wiring is

broken or its armature is

Sticking

7. The feed pump blades are

sticking, and therefore not

operating

8. The drive gear or woodruff key

is broken

Supply fuel and bleed the system

Clean or replace

Clean or replace

Bleed the system

Repair

Repair or replace

Repair or replace

Replace

2. Injection timing is incorrect

1. The drive gear or belt

connections are incorrect

2. The injection pump is

incorrectly installed on the

engine

3. The roller holder assembly’s

roller or pin is worn excessively

4. The plunger is worn excessively

Repair

Repair and adjust injection timing

Replace the assembly

Replace the distributor assembly

3. The nozzle does not operate

1. The nozzle or nozzle holder is

functioning incorrectly

Inspect. then repair or replace

4. The engine operates. but only

for short time

1. The pipe(s) to the injection

pump is blocked. or the fuel

filter is clogged

2. The fuel oil contains air or water

3. The feed pump’s delivery

quantity (or pressure) is

insufficient

Clean or replace the pipe(s) or fuel

filter

Bleed of air or replace the fuel oil

Repair or replace

5. The engine “knocks”

1. The injection timing is too

advanced

2. The nozzle or nozzle holder is

functioning incorrectly

Readjust the timing

Inspect. then repair or replace