6. FUEL INJECTION EQUIPMENT

134

6.2.3 Disassembly and reassembly of fuel feed pump

(1) Disassembly

1) Remove the fuel feed pump mounting nut, and take the fuel feed pump off the fuel injection pump.

2) Clean the fuel feed pump assembly with fuel oil.

3) After checking the orientation of the arrow on the cover, make match marks on the upper body and

cover, remove the small screw, and disassemble the cover, upper body and lower body.

(2) Reassembly

1) Clean all parts with fuel oil, inspect, and replace any defective parts.

2) Replace any packing on parts that have been disassembled.

3) Make sure that the intake valve and discharge valve on upper body are mounted in the proper

direction , and that you don’t forget the valve packing.

4) Assemble the diaphragm into the body, making sure the diaphragm mounting holes are lined up

(do not force).

5) Align the match marks on the upper body of the pump and cover, and tighten the small screws

evenly.

6.2.4 Fuel feed pump inspection

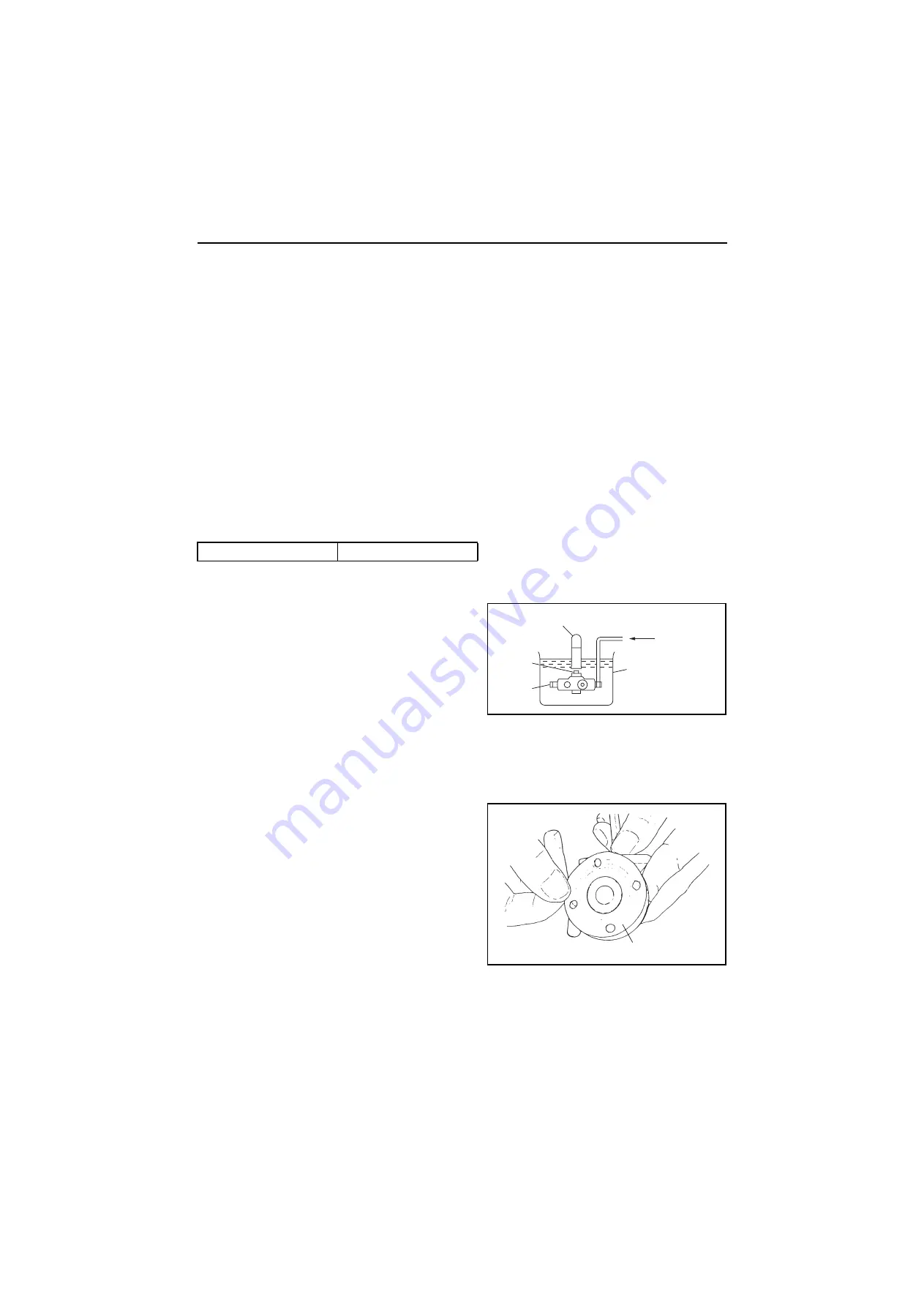

(1) Place the fuel feed pump in kerosene, cover

the discharge port with your finger, move the

priming lever and check for air bubbles

(Repair or replace any part which emits air

bubbles).

(2) Attach a vinyl house to the fuel feed pump intake, keep the pump at the specified depth

from the fuel oil surface, move the priming lever by hand and check for sudden spurts of

fuel oil from the discharge port. If oil is not spurted out, inspect the diaphragm and

diaphragm spring and repair/replace as necessary.

(3) Diaphragm inspection

Parts of the diaphragm that are repeatedly burned will

become thinner or deteriorate over a long period of

time.

Check the diaphragm and replace if necessary.

N•m(kgf•m)

Tightening torque

1.47-2.45 (0.15-0.25)

Measuring cylinder

Tappet

Blocked

Air pressure kg/cm

3

Container filled

with light oil

Diaphragm