ELECTRICAL COMPONENTS

8-64

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

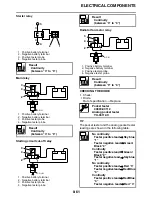

a. Connect the lean angle sensor coupler to

the wire harness.

b. Connect the pocket tester (DC 20 V) to the

lean angle sensor coupler as shown.

c. Incline the lean angle sensor.

d. Measure the lean angle sensor output volt-

age.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EASB296358

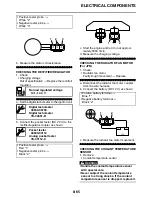

CHECKING THE STARTER MOTOR OPERA-

TION

1. Check:

• Starter motor

Does not operate

Perform the electric

starting system troubleshooting, starting

with step 4.

Refer to “ELECTRIC STARTING SYSTEM”

on page 8-6.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the positive battery terminal “1” and

starter motor lead “2” with a jumper lead “3”.

EWA

WARNING

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace it.

b. Check the starter motor operation.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS28150

CHECKING THE STATOR COIL

1. Disconnect:

• Stator coil coupler

(from the wire harness)

2. Check:

• Stator coil resistance

Out of specification

Replace the stator

coil.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Connect the pocket tester (

1) to the sta-

tor coil coupler as shown.

Lean angle sensor output voltage

Operating angle

45 °

Output voltage up to operating

angle

3.6–4.4 V

Output voltage over operating an-

gle

0.3–1.4 V

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

Test harness-lean angle sensor

(6P)

90890-03209

YU-03209

• Positive tester probe

Yellow/Green “1”

• Negative tester probe

Black/Blue “2”

2

1

°

45

°

45

Stator coil resistance

0.528–0.792

(W–W)

Pocket tester

90890-03112

Analog pocket tester

YU-03112-C

• Positive tester probe

White “1”

• Negative tester probe

White “2”

• Positive tester probe

White “1”

• Negative tester probe

White “3”

Summary of Contents for YZ 2016 Series

Page 6: ...EASB296006 YAMAHA MOTOR CORPORATION U S A YZ MOTORCYCLE LIMITED WARRANTY...

Page 10: ......

Page 31: ...CONTROL FUNCTIONS 1 19 a 2...

Page 63: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 22...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29...

Page 72: ...CABLE ROUTING DIAGRAM 2 31 EASB296066 CABLE ROUTING DIAGRAM...

Page 74: ...CABLE ROUTING DIAGRAM 2 33...

Page 76: ...CABLE ROUTING DIAGRAM 2 35...

Page 78: ...CABLE ROUTING DIAGRAM 2 37...

Page 80: ...CABLE ROUTING DIAGRAM 2 39...

Page 82: ...CABLE ROUTING DIAGRAM 2 41...

Page 84: ...CABLE ROUTING DIAGRAM 2 43...

Page 86: ...CABLE ROUTING DIAGRAM 2 45...

Page 262: ...OIL PUMP AND BALANCER GEAR 5 63 a 2 10 b 2 9 1 b 5 3 a 4 10 5 9 3 E c d 6 7 8 8 b 6...

Page 282: ...TRANSMISSION 5 83...

Page 302: ...8 CHECKING THE INTAKE AIR TEMPERATURE SENSOR 8 68 CHECKING THE FUEL INJECTOR 8 68...

Page 317: ...CHARGING SYSTEM 8 15...

Page 321: ...COOLING SYSTEM For JPN 8 19...

Page 351: ...FUEL PUMP SYSTEM 8 49...

Page 352: ...ELECTRICAL COMPONENTS 8 50 EASB296346 ELECTRICAL COMPONENTS EASB296347 7 8 9 1 3 2 4 5 6...

Page 354: ...ELECTRICAL COMPONENTS 8 52 11 10 9 2 3 1 6 7 8 4 5...

Page 356: ...ELECTRICAL COMPONENTS 8 54 EASB296348 CHECKING THE SWITCHES 4 1 3 2 B B Sb B B B B B B B B...

Page 378: ...LIST OF SELF DIAGNOSTIC AND FAIL SAFE ACTIONS 9 7...