PERIODIC MAINTENANCE

3-1

EAS20450

PERIODIC MAINTENANCE

EAS20460

INTRODUCTION

This chapter includes all information necessary to perform recommended checks and adjustments.

If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a

longer service life and reduce the need for costly overhaul work. This information applies to vehicles

already in service as well as to new vehicles that are being prepared for sale. All service technicians

should be familiar with this entire chapter.

EAS13S1007

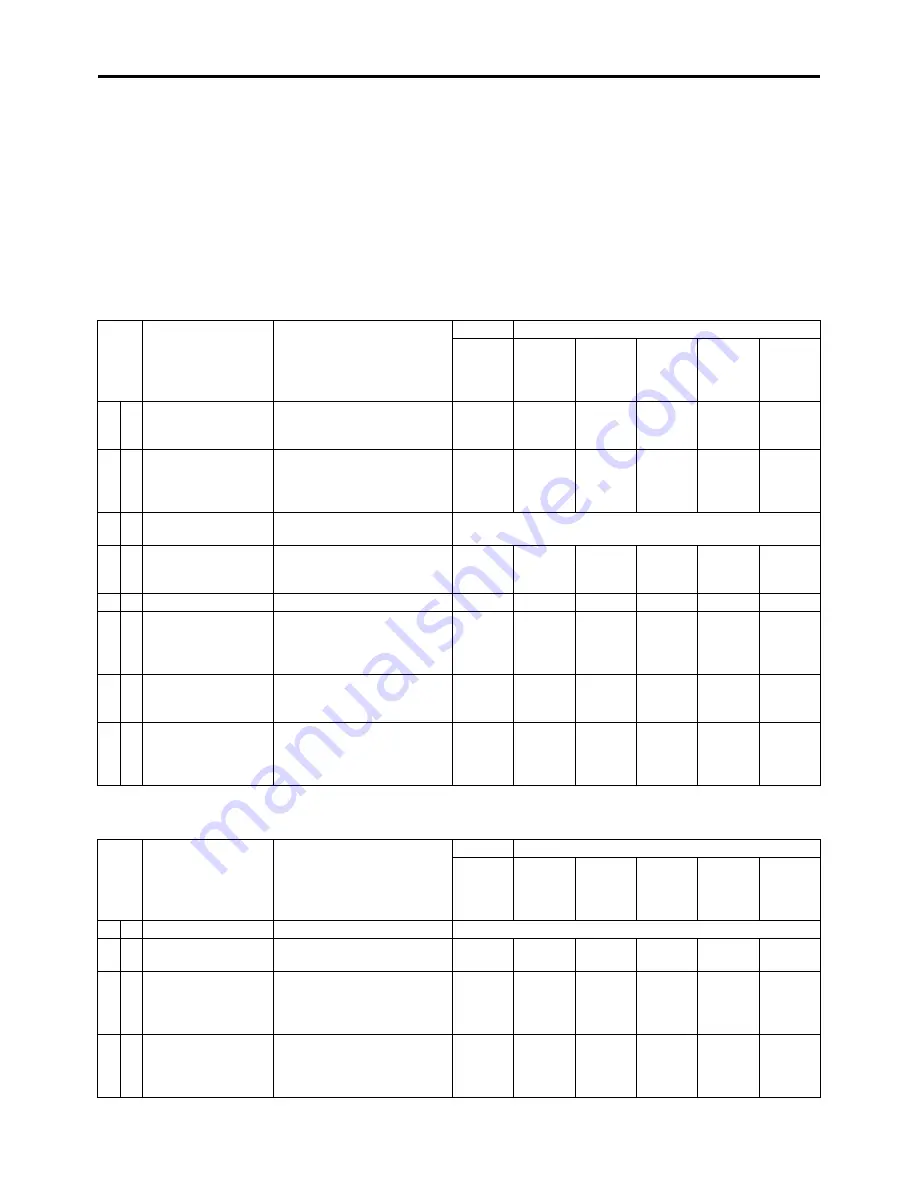

PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL SYSTEM

EAS13S1008

GENERAL MAINTENANCE AND LUBRICATION CHART

NO.

ITEM

ROUTINE

INITIAL

ODOMETER READING

600 mi

(1000 km)

or

1 month

4000 mi

(7000 km)

or

6 months

8000 mi

(13000 km)

or

12 months

12000 mi

(19000 km)

or

18 months

16000 mi

(25000 km)

or

24 months

20000 mi

(31000 km)

or

30 months

1

*

Fuel line

• Check fuel hoses for cracks or

damage.

• Replace if necessary.

√

√

√

√

√

2

*

Spark plugs

• Check condition.

• Adjust gap and clean.

• Replace every 8000 mi

(13000 km) or 12 months.

√

Replace.

√

Replace.

√

3

*

Valve clearance

• Check and adjust valve clear-

ance when engine is cold.

Every 26600 mi (42000 km)

4

*

Crankcase breather

system

• Check breather hose for

cracks or damage.

• Replace if necessary.

√

√

√

√

√

5

*

Fuel injection

• Adjust synchronization.

√

√

√

√

√

6

*

Exhaust system

• Check for leakage.

• Tighten if necessary.

• Replace gasket(s) if neces-

sary.

√

√

√

√

√

7

*

Evaporative emis-

sion control system

(For California only)

• Check control system for dam-

age.

• Replace if necessary.

√

8

*

Air induction system

• Check the air cut-off valve,

reed valve, and hose for dam-

age.

• Replace any damaged parts.

√

√

NO.

ITEM

ROUTINE

INITIAL

ODOMETER READING

600 mi

(1000 km)

or

1 month

4000 mi

(7000 km)

or

6 months

8000 mi

(13000 km)

or

12 months

12000 mi

(19000 km)

or

18 months

16000 mi

(25000 km)

or

24 months

20000 mi

(31000 km)

or

30 months

1

*

Air filter element

• Replace.

Every 24000 mi (37000 km)

2

*

Clutch

• Check operation.

• Adjust or replace cable.

√

√

√

√

√

√

3

*

Front brake

• Check operation, fluid level,

and for fluid leakage.

• Replace brake pads if neces-

sary.

√

√

√

√

√

√

4

*

Rear brake

• Check operation, fluid level,

and for fluid leakage.

• Replace brake pads if neces-

sary.

√

√

√

√

√

√

Summary of Contents for R6 2009

Page 1: ...SERVICE MANUAL YZFR6Y C 13S 28197 11 LIT 11616 22 51 2009 ...

Page 6: ......

Page 8: ......

Page 60: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 EAS20410 LUBRICATION DIAGRAMS 1 2 3 4 ...

Page 62: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 31 1 2 3 4 8 7 6 5 ...

Page 64: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 33 1 2 3 4 5 ...

Page 66: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 35 1 5 4 3 2 ...

Page 68: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 37 3 1 2 5 4 ...

Page 70: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 39 1 3 2 ...

Page 71: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 40 1 Oil pipe 2 Main axle 3 Drive axle ...

Page 72: ...COOLING SYSTEM DIAGRAMS 2 41 EAS20420 COOLING SYSTEM DIAGRAMS 1 2 3 4 ...

Page 74: ...COOLING SYSTEM DIAGRAMS 2 43 A A 2 1 3 4 5 6 7 8 6 13 8 9 15 14 9 10 11 12 ...

Page 76: ...CABLE ROUTING 2 45 EAS20430 CABLE ROUTING ...

Page 78: ...CABLE ROUTING 2 47 ...

Page 80: ...CABLE ROUTING 2 49 ...

Page 82: ...CABLE ROUTING 2 51 ...

Page 84: ...CABLE ROUTING 2 53 ...

Page 86: ...CABLE ROUTING 2 55 ...

Page 88: ...CABLE ROUTING 2 57 ...

Page 90: ...CABLE ROUTING 2 59 A A ...

Page 92: ...CABLE ROUTING 2 61 ...

Page 95: ......

Page 135: ......

Page 206: ...CHAIN DRIVE 4 71 1 2 3 a a New ...

Page 209: ......

Page 240: ...PICKUP ROTOR 5 31 ...

Page 286: ...TRANSMISSION 5 77 ...

Page 300: ...WATER PUMP 6 13 ...

Page 316: ...AIR INDUCTION SYSTEM 7 15 EAS27040 AIR INDUCTION SYSTEM 2 1 2 4 3 4 3 6 4 5 A A ...

Page 323: ......

Page 324: ...IGNITION SYSTEM 8 1 EAS27090 IGNITION SYSTEM EAS27110 CIRCUIT DIAGRAM ...

Page 330: ...ELECTRIC STARTING SYSTEM 8 7 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 336: ...CHARGING SYSTEM 8 13 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 339: ...CHARGING SYSTEM 8 16 ...

Page 340: ...LIGHTING SYSTEM 8 17 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 344: ...SIGNALING SYSTEM 8 21 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 351: ...SIGNALING SYSTEM 8 28 ...

Page 352: ...COOLING SYSTEM 8 29 EAS27300 COOLING SYSTEM EAS27310 CIRCUIT DIAGRAM ...

Page 355: ...COOLING SYSTEM 8 32 ...

Page 356: ...FUEL INJECTION SYSTEM 8 33 EAS27330 FUEL INJECTION SYSTEM EAS27340 CIRCUIT DIAGRAM ...

Page 395: ...FUEL INJECTION SYSTEM 8 72 ...

Page 396: ...FUEL PUMP SYSTEM 8 73 EAS27550 FUEL PUMP SYSTEM EAS27560 CIRCUIT DIAGRAM ...

Page 399: ...FUEL PUMP SYSTEM 8 76 ...

Page 400: ...ELECTRICAL COMPONENTS 8 77 EAS27970 ELECTRICAL COMPONENTS ...

Page 402: ...ELECTRICAL COMPONENTS 8 79 1 5 4 3 2 6 7 8 9 10 12 13 11 14 15 16 17 18 ...

Page 404: ...ELECTRICAL COMPONENTS 8 81 EAS27980 CHECKING THE SWITCHES ...

Page 431: ......

Page 432: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...