3

Adjustment

3-11

4.

Adjusting shutter looseness (T4L/T4LH/T5L/T5LH/T6L)

The shutter may elongate with continued use. In such cases, adjust as follows.

c

CAUTION

Be sure to wear safety gloves before starting the work. If you touch any steel material part with bare hands, this

may cause rust.

Prepare an appropriate Phillips screwdriver.

c

CAUTION

When the robot is installed vertically, slowly move the robot at a jOG speed to check the position where the

shutter becomes loose mostly before entering the safety enclosure.

1

Turn off the controller power.

2

Place a sign indicating the robot is being adjusted.

Place a sign indicating the robot is being adjusted, to keep others from operating the controller or

operation panel.

3

Enter the safety enclosure.

4

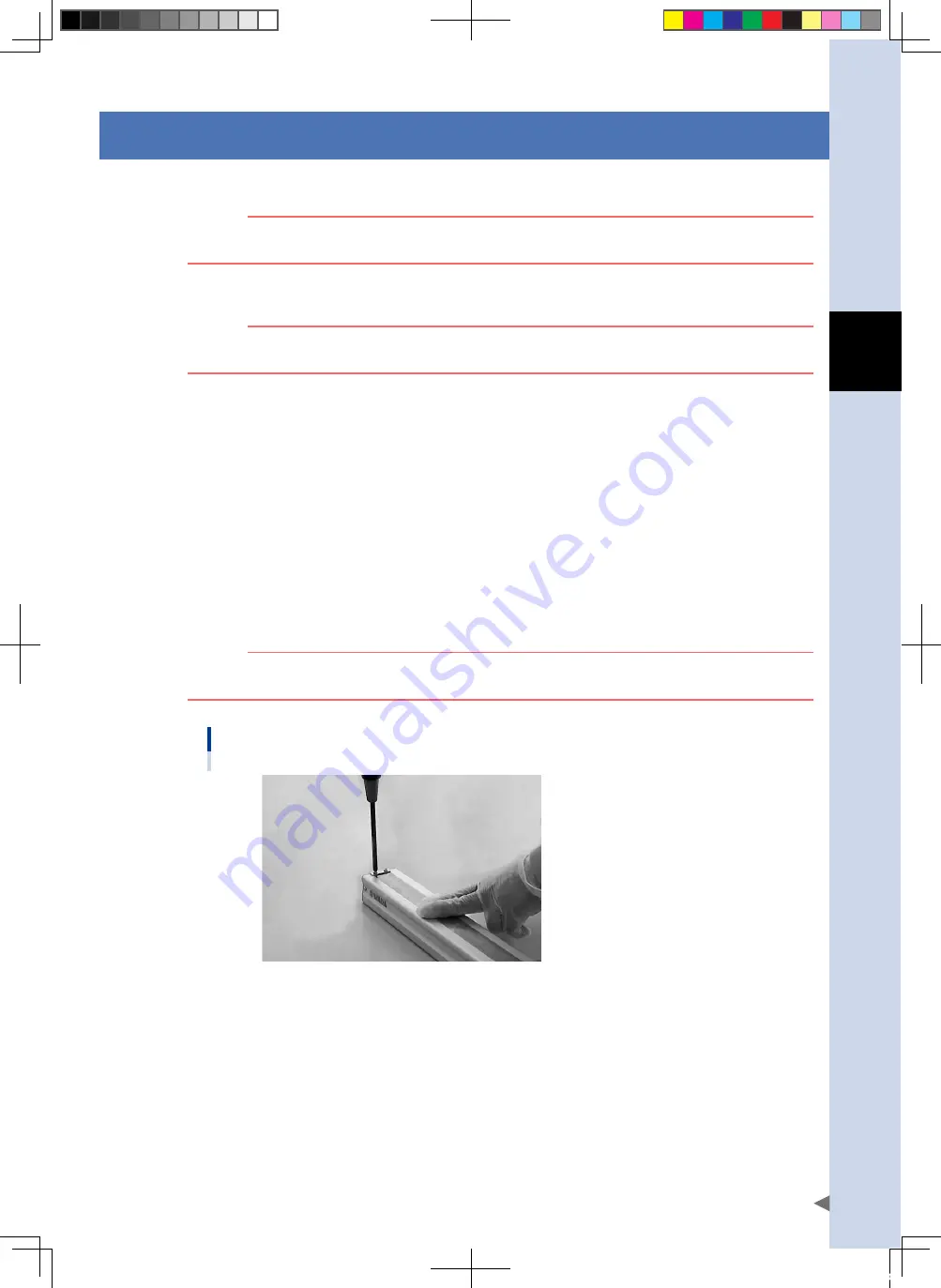

Loosen the screw lightly.

Lightly loosen the screws (2) securing the shutter on the end block side. (At this time, do not remove the

screws.)

5

Secure the shutter.

While stretching the shutter by fingers, tighten the screws to secure the shutter so that it does not

become loose.

c

CAUTION

Do not press down on the shutter with excessive force.

Pressing down hard on the shutter may cause the shutter to warp.

Adjusting the looseness

53303-A1-00

FLIP-X_maint_E_V1.50.indb 11

18/05/15 15:01

Summary of Contents for FLIP-X Series

Page 2: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 00...

Page 40: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 41: ...Chapter 1 Overview Contents 1 Overview 1 1 FLIP X_maint_E_V1 50 indb 1 18 05 15 15 01...

Page 42: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 44: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 46: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 60: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 72: ...FLIP X_maint_E_V1 50 indb 12 18 05 15 15 01...

Page 74: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...

Page 104: ...FLIP X_maint_E_V1 50 indb 2 18 05 15 15 01...