CHASSIS

3-20

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

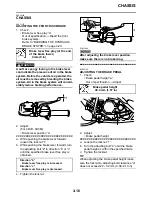

EAS21350

BLEEDING THE HYDRAULIC BRAKE SYS-

TEM

WARNING

EWA13100

Bleed the hydraulic brake system when-

ever:

• the system is disassembled.

• a brake hose is loosened, disconnected

or replaced.

• the brake fluid level is very low.

• brake operation is faulty.

TIP

• Be careful not to spill any brake fluid or allow

the brake master cylinder reservoir or brake

fluid reservoir to overflow.

• When bleeding the hydraulic brake system,

make sure there is always enough brake fluid

before applying the brake. Ignoring this pre-

caution could allow air to enter the hydraulic

brake system, considerably lengthening the

bleeding procedure.

• If bleeding is difficult, it may be necessary to

let the brake fluid settle for a few hours.

Repeat the bleeding procedure when the tiny

bubbles in the hose have disappeared.

1. Bleed:

• Hydraulic brake system

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

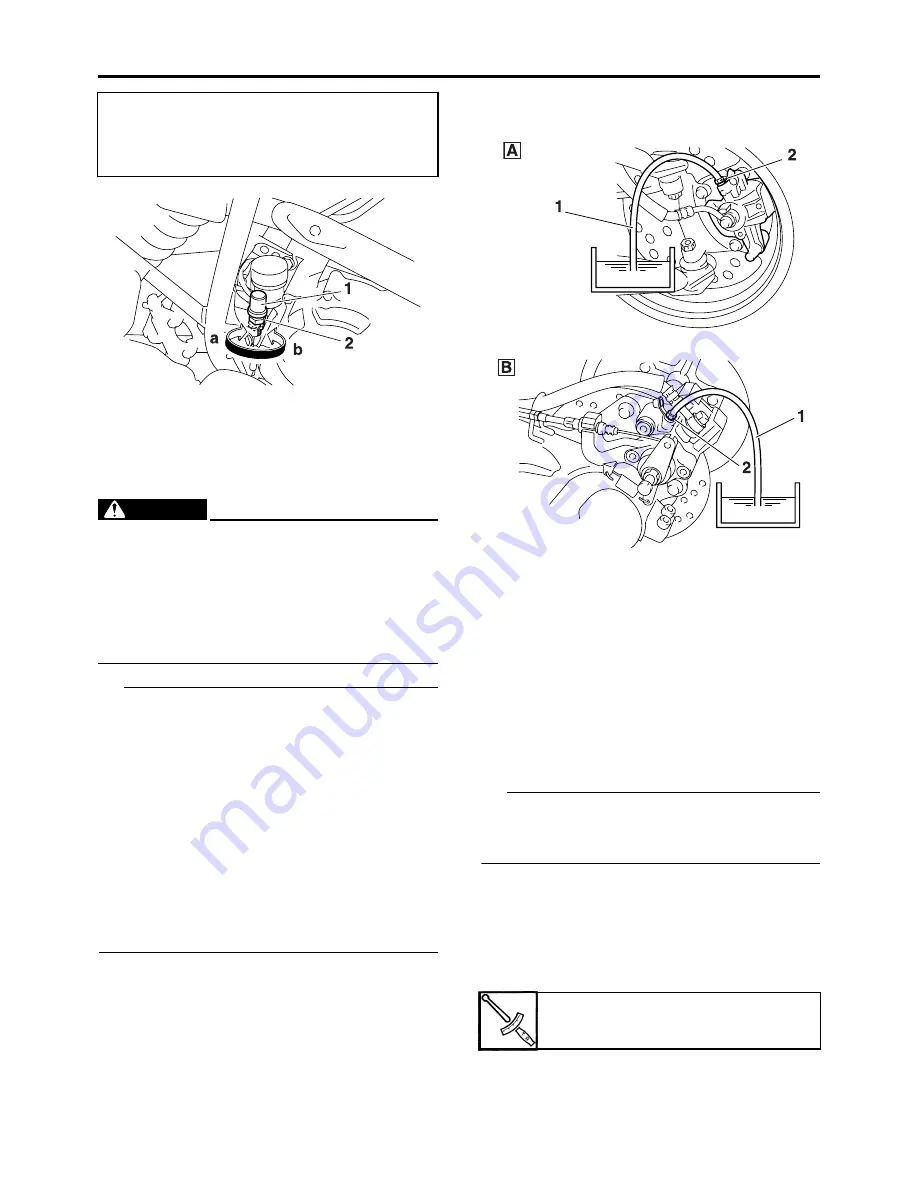

a. Fill the brake fluid reservoir to the proper

level with the recommended brake fluid.

b. Install the diaphragm (brake master cylin-

der reservoir or brake fluid reservoir).

c. Connect a clear plastic hose “1” tightly to

the bleed screw “2”.

d. Place the other end of the hose into a con-

tainer.

e. Slowly apply the brake lever or brake pedal

several times.

f.

Fully pull the brake lever or fully press

down the brake pedal and hold it in posi-

tion.

g. Loosen the bleed screw.

TIP

Loosening the bleed screw will release the

pressure and cause the brake lever to contact

the grip or the brake pedal to fully extend.

h. Tighten the bleed screw and then release

the brake lever or brake pedal.

i.

Repeat steps (e) to (h) until all of the air

bubbles have disappeared from the brake

fluid in the plastic hose.

j.

Tighten the bleed screw to specification.

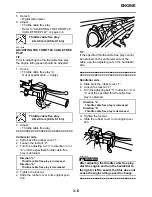

Direction “a”

Brake light comes on sooner.

Direction “b”

Brake light comes on later.

A. Front

B. Rear

Bleed screw

6 Nm (0.6 m·kg, 4.4 ft·lb)

Summary of Contents for 2009 YFM25RY

Page 1: ...SERVICE MANUAL YFM25RY YFM25RSEY YFM25RSE2Y 4D3 28197 11 LIT 11616 22 09 2009 ...

Page 8: ......

Page 39: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 20 ...

Page 42: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 23 EAS20410 LUBRICATION DIAGRAMS ...

Page 44: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25 ...

Page 46: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 ...

Page 47: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 28 1 Oil cooler 2 Oil hose 1 3 Oil hose 2 ...

Page 48: ...CABLE ROUTING 2 29 EAS20430 CABLE ROUTING ...

Page 50: ...CABLE ROUTING 2 31 ...

Page 52: ...CABLE ROUTING 2 33 ...

Page 54: ...CABLE ROUTING 2 35 ...

Page 56: ...CABLE ROUTING 2 37 ...

Page 58: ...CABLE ROUTING 2 39 ...

Page 60: ...CABLE ROUTING 2 41 ...

Page 62: ...CABLE ROUTING 2 43 ...

Page 65: ......

Page 143: ...HANDLEBAR 4 42 Throttle cable free play 2 0 4 0 mm 0 08 0 16 in ...

Page 162: ...CHAIN DRIVE 4 61 ...

Page 165: ......

Page 240: ...CARBURETOR 6 9 ...

Page 242: ...IGNITION SYSTEM 7 1 EAS27090 IGNITION SYSTEM EAS27100 CIRCUIT DIAGRAM ...

Page 246: ...ELECTRIC STARTING SYSTEM 7 5 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 252: ...CHARGING SYSTEM 7 11 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 255: ...CHARGING SYSTEM 7 14 ...

Page 256: ...LIGHTING SYSTEM 7 15 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 260: ...SIGNALING SYSTEM 7 19 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 264: ...CARBURETOR HEATING SYSTEM 7 23 EAS27490 CARBURETOR HEATING SYSTEM EAS27500 CIRCUIT DIAGRAM ...

Page 267: ...CARBURETOR HEATING SYSTEM 7 26 ...

Page 268: ...ELECTRICAL COMPONENTS 7 27 EAS27972 ELECTRICAL COMPONENTS ...

Page 270: ...ELECTRICAL COMPONENTS 7 29 EAS27980 CHECKING THE SWITCHES ...

Page 284: ...ELECTRICAL COMPONENTS 7 43 ...

Page 291: ......

Page 292: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...

Page 293: ...WIRING DIAGRAM YFM25RY YFM25RSEY YFM25RSE2Y ...