– 51 –

CHAS

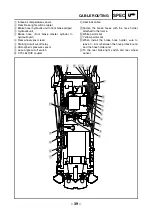

FRONT WHEEL AND BRAKE DISCS

EAS00514

CHASSIS

FRONT WHEEL AND BRAKE DISCS

Order

Job/Part

Q’ty

Remarks

Removing the front wheel and brake

discs

Remove the parts in the order listed.

NOTE:

Place the motorcycle on a suitable stand

so that the front wheel is elevated.

1

Reflector

2

For AUS only

2

Brake caliper (left and right)

2

Refer to “REMOVING/

INSTALLING THE

FRONT WHEEL” in chap-

ter 4.

(Manual No.: 5JW1-AE1)

3

Wheel axle pinch bolt

1

Loosen.

4

Front wheel axle

1

5

Front wheel

1

6

Collar (left)

1

7

Collar (right)

1

8

Brake disc (left and right)

2

For installation, reverse the removal

procedure.

Summary of Contents for 2003 FJR1300

Page 1: ...2003 FJR1300 R FJR1300A R 5JW1 AE4 SUPPLEMENTARY SERVICE MANUAL ...

Page 2: ......

Page 159: ......

Page 160: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...