7

Inspection and maintenance

03.2018

77

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

7.12

Overload safety device

7.12.1

Testing overload safety device

If an overload is detected, the wire rope hoist is switched off in the upwards direction.

Only lowering is then possible. Lifting is not possible until the wire rope hoist has been

unloaded.

1.

Attach a test load of 100% maximum working load + 10% overload and take load up

slowly. After the rope is tautened the overload safety device must disconnect the

hoist. If the hoist is not disconnected, see original operating instructions of overload

device.

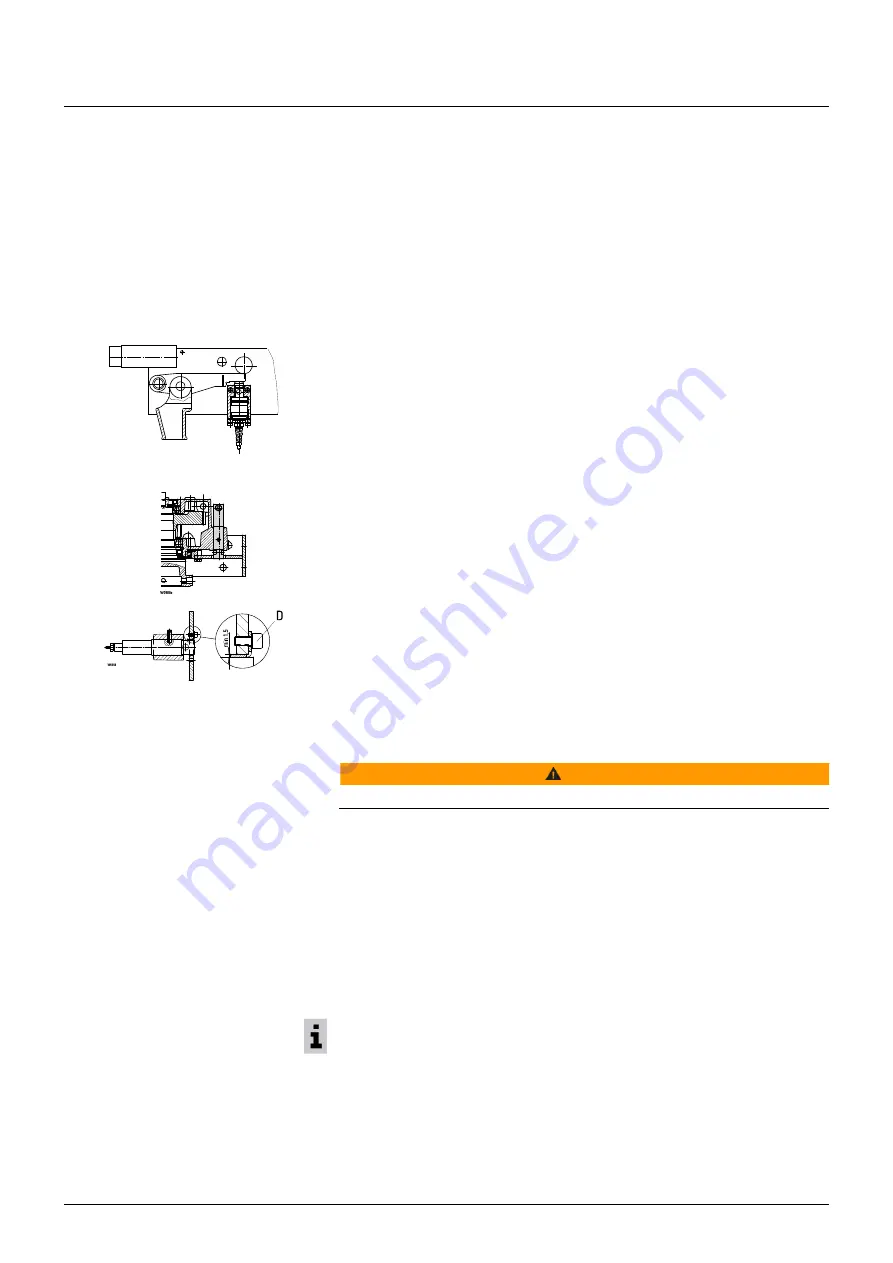

Fig. 84

Fig. 85

7.12.2

Maintenance of overload safety device with pressure sensor

1.

After off-loading hoist, check all moving parts for ease of movement.

2.

Clean without dismantling and grease from the outside with a thin-bodied lubricant.

7.12.3

Maintenance of overload safety device with shear force sensor

1.

Check plate thickness (

min. 0.059 in.

)

2.

If necessary, replace plate after removing screw (D).

7.13

Crane test

WARNING

Safety hazard

. Make sure that the crane test is performed by a qualified person.

Test loads must be provided by the owner.

The crane test is part of commissioning the wire rope hoist. The test comprises:

Dynamic test: 1.1 × maximum working load

Test each direction of movement at slow and fast speed. The crane must operate

smoothly during the test.

Static test: 1.25 × maximum working load

The test load must not be lifted more than max. 7.9 in from the ground at slow speed

during the static test.

To enable this test to be performed, a qualified person can raise the overload cut-off

threshold following the original operating instructions of the overload device.

W0788