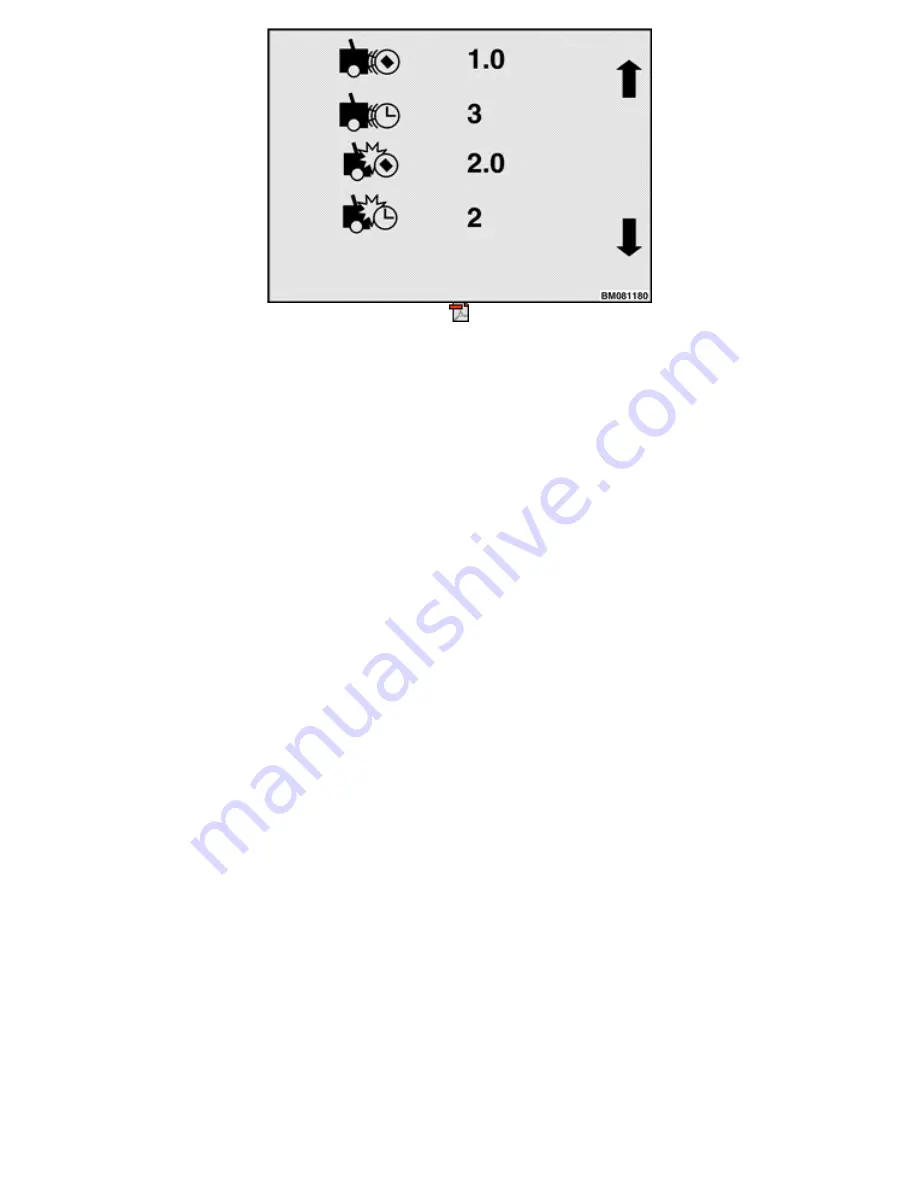

Figure 54. Impact Monitor Settings Screen

Impact Detection

The impact monitor can detect both hard and soft impacts.

An example of a hard impact is a truck colliding with a steel column in a warehouse which causes the truck to

stop suddenly. In this case the impact force is very strong but it occurs during a short time period.

An example of a soft impact is a truck rolling over and crushing a wooden pallet. In this case the impact force

is much less than experienced with a hard impact but it lasts for a significantly longer time period.

Setting Adjustments

Use the

2

and

3

soft keys to move up or down through the current values for the four settings for Impact Force

and Impact Times. When there is a box around the setting you want to change, press the

Enter Key

, then use

the

2

or

3

soft key to step through the valid values for that setting.

The Soft Impact Force, the setting at the top of the screen, can be set to a value in the range 0.2 to 2.5 g., in

tenths of gravitational force.

The Soft Impact Time, the second setting down from the top, can be adjusted to require the impact monitor to

see an impact force greater than the Soft Impact Force for 1 to 12 samples before a soft impact event will be

reported.

The Hard Impact Force, the third setting down, can be set to a value in the range 0.5 to 3.0 g., in tenths of

gravitational force.

The Hard Impact Time, the forth setting down from the top, can be adjusted to require the impact monitor to

see an impact force greater than the Hard Impact Force for 1 or 2 samples before a hard impact event will be

reported.

The Hard Impact Force, the third setting down, can be set to a value in the range 0.5 to 3.0 g., in tenths of

gravitational force.

Initial Adjustment of Soft and Hard Impact Settings

NOTE:

When adjusting the impact sensor settings, be sure to:

Adjust the truck to the lowest Soft Impact Force setting, the Soft Impact Time set to 6, and the highest Hard

Impact Force Setting. Drive the truck at the fastest operational speed for the environment. Apply the brakes to

bring the truck to an abrupt stop. Determine if an impact event has occurred.

Increase either the Soft Impact Force setting until the vehicle can be abruptly stopped with the service brake

Summary of Contents for ERC030VA

Page 8: ...Figure 3 Supervisor Flowchart Sheet 1 of 4 ...

Page 9: ...Figure 3 Supervisor Flowchart Sheet 2 of 4 ...

Page 10: ...Figure 3 Supervisor Flowchart Sheet 3 of 4 ...

Page 11: ...Figure 3 Supervisor Flowchart Sheet 4 of 4 Table 1 Supervisor Menu Flowchart A B C D E F G H ...

Page 21: ...Hydraulics Icon Alert Screens Cycle the Key Secure Battery Release Park Brake ...

Page 22: ...Operator Out of Seat Release Pedal Release Hydraulic Input Traction Switch ...

Page 23: ...Hydraulic Switch Temperature Too High Lift Limit Charge Battery ...

Page 26: ...Display Title Screen Status Title Screen Truck Setup Title Screen ...

Page 105: ...Figure 71 Steering Wheel Number of Turns Valid Entry ...