6 Operation

6.1 Startup and operation

For instructions about the system operation, see the System Installation and

Operation manual.

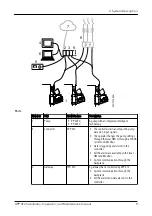

6.2 LED indicators

PWR

DI1

DI2

DI3

DI4

DO1

DO2

DO3

DO4

ALARM A

ALARM B

RUN

COMMS

RS485

USB

NODE

ADDRESS

1 2

3

4 5

6

7

8

9

0

WS010862A

Table 1: Normal operation

LED

Description

Color

Indication

PWR

Power

Green

The power is on.

21.6-26.4 V

–

The power is off.

Orange

20.0-21.6 V

26.4-29.4 V

Red

<20.0 V

>29.4 V

DI1 – DI4

Digital inputs

Green

The digital input is

active.

–

The digital input does

not receive a signal.

DO1 – DO4

Digital outputs

Green

The digital output is

active.

–

The digital output is

inactive.

ALARM A

Alarm, Class A

Flashing red

The alarm is not

acknowledged. The

alarm condition is either

present or has ceased.

6 Operation

APP 412 Installation, Operation, and Maintenance manual

21