0/99

1

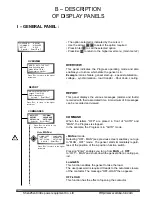

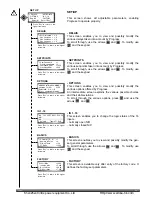

CONTROL EQUIPMENT

1. Ammeter

2. Ammeter switch

3. Voltmeter

4. Voltmeter switch

5. Frequency/RPM meter

6. Front lighting

7. Hours counter

8. Oil pressure gauge

9. Coolant temperature gauge

10. Battery voltage gauge

11. Fuel level gauge

12. Emergency stop button (remote in Version

IV & V)

13. MICS Progress

14. 4-position function switch

15. Oil temperature gauge

16. Battery ammeter gauge

17. Shutdown extractor light

18. MDEC synthesis alarm light

19. Lack of water preheating light

20. Retention tank warning light

21. Test lamps push button

Progress can be factory configured in several ways.

Any further changes will have to be submitted to our company prior consent.

A

Http://www.xinke-hk.com

ShenZhen XinKe power equipment Co .Ltd