Service Parts Disassembly

Phaser 6600 and WorkCentre 6605Xerox Internal Use Only

Service Manual

4-104

MFP IP Board

(PL18.1.22)

Note:

When replacing the IP Board, be sure to transfer the NVRAM and, if installed, Optional RAM,

Hard Disk or Wireless Kit to the new IP Board.

1.

Remove the Front Door Assembly. (page 4-128)

2.

Remove the Left Cover Assembly. (page 4-136)

3.

Remove the Lower Left Hand Rear Cover. (page 4-124)

4.

Remove the Fax Board. (page 4-97)

5.

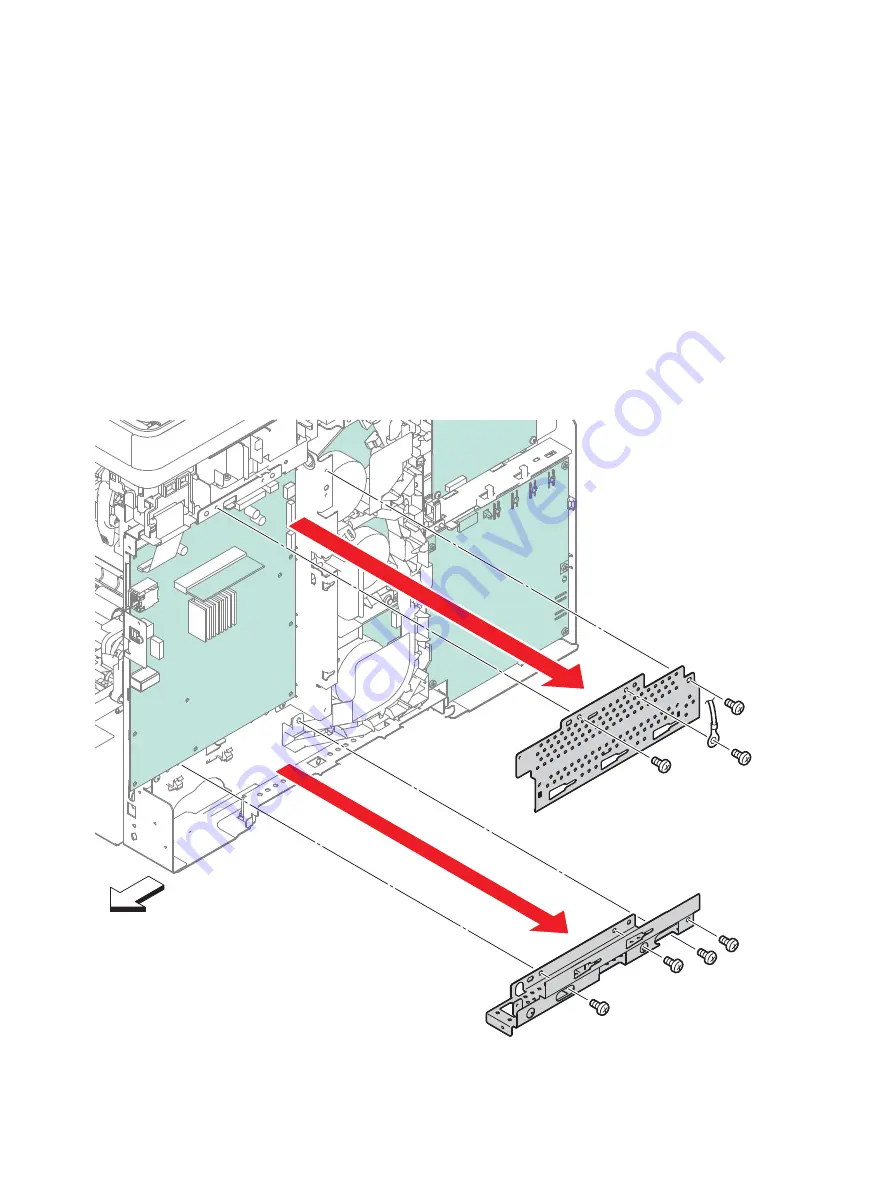

Remove the three screws (silver, 6mm) that attach the MFP Top IP Board Plate (PL18.1.19) and

remove the plate by removing the grounding wire.

6.

Remove the four screws (silver, 6mm) that attach the IP Board Bottom Plate (PL18.1.20) to the

printer and remove the plate.

s6600-116

Rear

Summary of Contents for WorkCentre 6605

Page 2: ......

Page 4: ...Phaser 6600 and WorkCentre 6605 Xerox Internal Use Only Service Manual ii ...

Page 352: ...Image Quality Phaser 6600 and WorkCentre 6605 Xerox Internal Use Only Service Manual 3 26 ...

Page 568: ...Parts Lists Phaser 6600 and WorkCentre 6605 Xerox Internal Use Only Service Manual 5 64 ...

Page 644: ...Wiring Phaser 6600 and WorkCentre 6605 Xerox Internal Use Only Service Manual 7 52 ...

Page 654: ...Phaser 6600 and WorkCentre 6605 Xerox Internal Use Only Service Manual A 10 ...

Page 660: ...Index Phaser 6600 and WorkCentre 6605 Service Manual I 6 ...

Page 661: ......