When the

displays, cover the sensor with the small piece of the web.

This allows the Web Registration Module to detect the dark value.

•

• When

displays, ensure that the sensor is not covered. This allows

the Web Registration Module to detect the bright value.

6. When finished, select

.

The material setup for the Secondary (Downstream) CiPress

™

Paper Sensor is complete.

Optimize Gain for Primary (Upstream) CiPress

™

This procedure is used to set individual gain values for the different modes on the Web

Registration Module.

1. Select

.

2. Select

simultaneously.

3. Select

.

4. Select

.

5. Select

.

6. Select

and

simultaneously to reset the Web Registration Guide gain to

0.5.

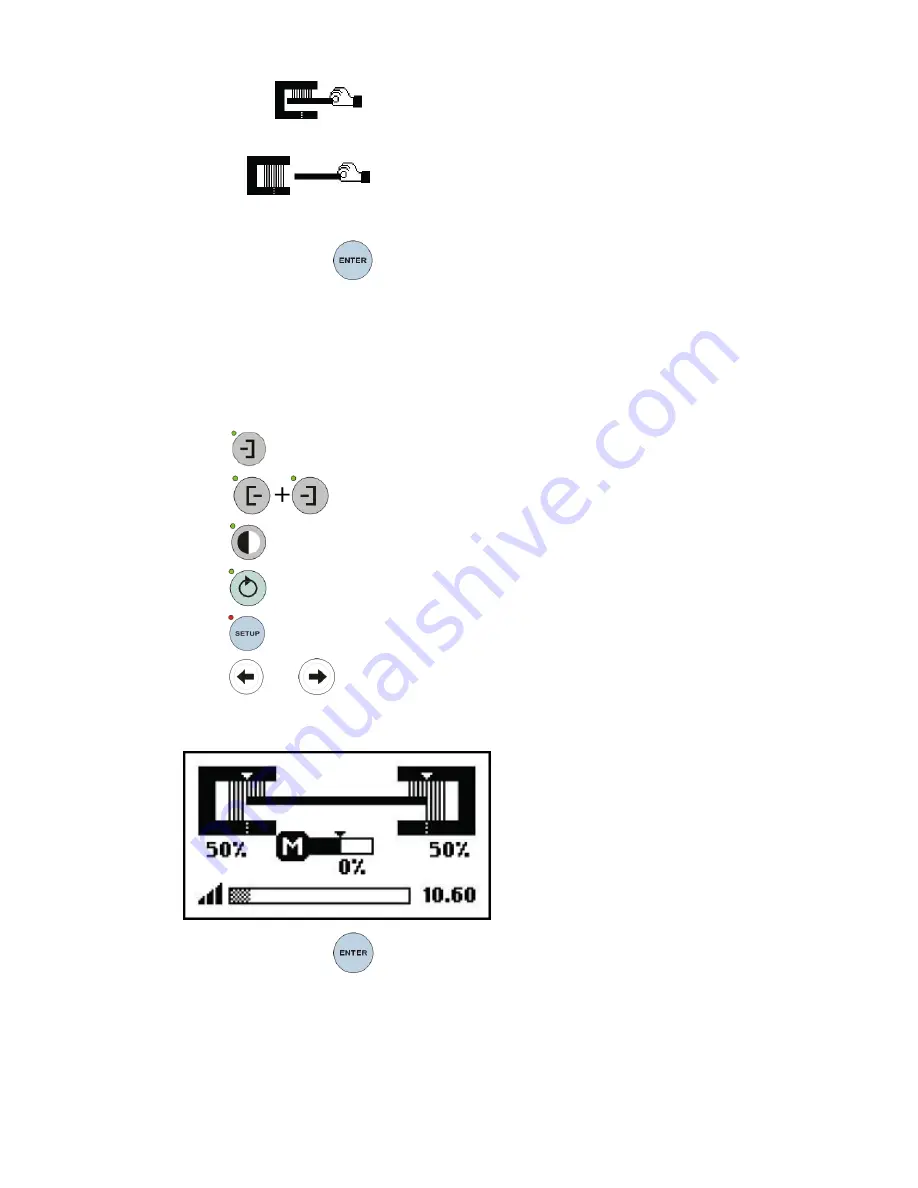

Example of Web Registration Module Screen showing Gain Scale (shown at bottom).

7. When finished, select

.

The optimize gain setup for the Primary (Upstream) CiPress

™

Paper Sensor is complete.

5-13

Xerox

®

CiPress™ 325 / 500 Production Inkjet System

Customer Help Information

Problem Solving

Summary of Contents for CiPress 325

Page 16: ...Xerox CiPress 325 500 Production Inkjet System 1 8 Customer Help Information CiPress System...

Page 28: ...Xerox CiPress 325 500 Production Inkjet System 2 12 Customer Help Information Power Management...

Page 30: ...Xerox CiPress 325 500 Production Inkjet System 3 2 Customer Help Information Web Setup...

Page 191: ......

Page 192: ......