ABOUT THE APPLIANCE

6 720 803 688 (2012/11)

4

2.3

DATA PLATE

On the data plate you will find details of the part number, appliance

output and approval data.

On the hybrid manager, a data plate is affixed to the right hand side

panel of the casing.

Fig. 1

Data plate on the hybrid manager (internal unit)

[1]

Unit data

[2]

Serial number

On the external unit, the data plate is located under the service cover.

2.4

GENERAL INFORMATION ON HEAT PRODUCTION

Buildings can be heated efficiently with condensing boilers and air to

water heat pumps. However, these two technologies have different

performance characteristics.

Condensing boilers as well as air to water heat pumps use energy gained

from fossil fuels. In condensing boilers, gas is burnt directly inside the

appliance.

Air to water heat pumps use electrical energy which has been obtained

from a number of different sources. This includes fossil-fuel-burning

power stations. These are typically around 40 % efficient in converting

fuel to useful electricity. Although an air to water heat pump is far more

efficient than a condensing boiler at converting its input energy

(electricity) into heat, the electricity used has a larger amount of fossil-

fuel consumption attached. This consumption of fossil fuels is referred

to as the primary energy factor (PEF).

The fan draws ambient air via the evaporator of the air to water heat

pump. This extracts heat from the ambient air. The compressor

mechanically increases the temperature and transfers it to the water

circuit.

The PEF of electricity is generally 2.3, the PEF of oil and gas is 1.1, the

PEF of mixed electric power 2.6. The coefficient of performance (COP)

of an air to water heat pump is, subject to outside temperature and water

flow temperature, between 2 and 5.5.

Depending on the current situation and heat demand, either the

condensing boiler or the air to water heat pump may offer a more

favourable energy-to-cost ratio.

The hybrid package integrates both technologies in one system and

thereby offers the opportunity to use either heat source optimally at any

time. Users can decide for themselves whether the emphasis should be

on primary energy consumption and/or whether costs take priority,

alternatively, a combination of primary energy and costs can be used.

GENERAL FUNCTIONS

The hybrid control module determines the proportion of the total energy

expenditure that will be covered by either the condensing boiler or the

external unit, thereby optimizing the efficiency of the heating system.

After flowing through the hybrid manager, the heating water returns

either directly to the heating system or first through the condensing

boiler and then onwards to the heating system.

A high efficiency (HE) pump integrated into the hybrid manager provides

the heating water circulation inside the hybrid manager. Only the HE

pump inside the hybrid manager runs as long as the air to water heat

pump operates on its own.

The pump inside the condensing boiler and the HE pump inside the

hybrid manager run concurrently if either the condensing boiler on its

own or condensing boiler and air to water heat pump operate

simultaneously.

A filter with sieve inside the hybrid manager protects the heat exchanger

and the heating system from contamination through small particles.

A flow switch with magnetic toggle switch ensures that the external unit

only operates as long as the water flow rate is adequate for the Hybrid

Manager.

The heat transfer between the refrigerant (R410A) and the heating

water takes place inside the heat exchanger of the Hybrid Manager.

AUTOMATIC DEFROST FUNCTION

Ice forms on the external unit at low temperatures (

7 °C). In the

temperature range of +7 °C to -9 °C, heat from the heating system water

is used briefly to automatically defrost the external unit.

During defrosting, the boiler remains available for heating the heating

water. The defrost cycle takes approx. 5 minutes.

The service cover may only be removed by a competent

person.

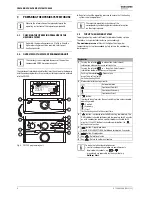

6720803688-01.1W

o

50W

0.43 A

R410A 2.50 kg (30m)

4.15 MPa

2.30 MPa

IPX4D

230V 50Hz

3A

(A2W35) = 3.852kW

(A7W35) = 4.704kW

(A2W35) = 3.14

(A7W35) = 4.42

5570 - XXX - XXXXX - 7716160030

2

1