7

* Both knife edges in the lower cutters

must be set equal to each other, and

be at the same height as the table

after the cutter, use a block (straight

strip of wood long so that it lies on the

two slide rails) as laid on the table and

on either side of the steel, screw up

the steel is so it just scrapes the

passport bit but not cut.

* The knife edges of the cutter in

grades shall be 1 mm above

cutter head. Use setting block, see

picture:

* Make sure the set screws for steel is

the lower position of the track (cutter:

the bottom) before

Allen screws drawn at one, to prevent

the knife edges are pressed by the

wedges.

Profile Steel in horizontal cutters

Profile knives can be fitted in the

cutters. Profile knives must always be

installed in pairs in the same lateral

position (opposite each other). If the

profile steel cutters can be mounted in

a protrusion

Under cutter

Profile depth of more than 10 mm shall

be placed so that they fit in the slots in

the table.

Installation and setup of profile steel

Put the wedge (D) and profile steel (E)

Insert the key and profile steel in the

side of the cutter where the keyway is

greater.

Slide the blade and the wedge in the

groove.

Measure and place the blades position

sideways.

Fix by screw (F) on the wedge.

Install an identical profile steel in the

same way on the opposite side.

Take help of the small tracks that are

on the cutter.

Summary of Contents for PH365

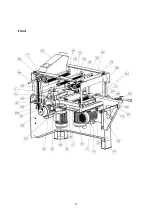

Page 18: ...18 Overview ...

Page 19: ...19 Front ...

Page 20: ...20 Front ...

Page 21: ...21 Backside ...

Page 22: ...22 Backside ...

Page 23: ...23 Left vertical cutter ...

Page 25: ...25 Upper cutter feed rollers ...