Gearless Lift Machine

WSG-08

with caliper disk brake

Operating Instructions

Be sure to check the base frame or founda-

tion loads by calculation before installing

the lift machine.

The lift machine may only be installed if the relevant

safety precautions have been met.

The machines can be used in lift systems with or without

a machine room.

When using the machine in a shaft, please

take the patent situation into consideration.

The machines may only be installed, electrically connected

and put into operation by trained specialist personnel. The

system-specific conditions and the requirements of the

system manufacturer or plant constructor must be met.

Cover the machine and especially the

brakes when doing any machining or dust-

producing work in the shaft or machine

room.

The measuring system is only accessible

from the rear side. Therefore, leave enough

space between the wall and the rear side of

the machine or ensure that the machine

can be moved away from the wall.

Degree of protection

Lift machines are designed with degree of protection

IP 41. Make sure that the cable entries to the terminal

boxes are sealed properly when making the electrical

installation.

Ambient conditions

The following ambient conditions must be ensured on

site:

Altitude:

max. 1,000 m a.s.l.

Ambient temperature:

- 5 ... 40°C

Max. rel. humidity:

85 % at 20°C (no moisture con-

densation)

Install the machine so that ventilation is not obstructed,

i.e. sufficient heat dissipation by convection and radia-

tion must be ensured.

The torque and power values indicated in the Technical

Data apply to the above ambient temperatures and alti-

tudes. In case of a deviating altitude and/or ambient

temperature, the reduction factors k shown in the

diagram below must be used.

M

permiss.

= k * M

N

P

permiss.

= k * P

N

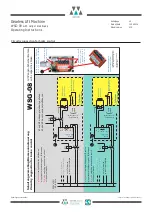

Fastening the machine

The rope force can be applied to the lift

machine in any direction.

The machine or base frame should be mount-

ed on rubber pads for vibration damping.

The machine is fastened using 4 M24 bolts (strength class

12.9; tightening torque: 1,150 Nm).

The permissible uneveness of the mounting surface is

0.1 mm. The mounting surface must be sufficiently dis-

tortion-resistant and stable to accommodate the forces

occurring in the system.

After completing the adjusting work or

after a breakdown, tighten all the fastening

bolts of the machine, using the specified

torque.

No welding work may be performed on the

lift machine, nor is it permissible to use the

machine as a mass point for welding work.

This could destroy the bearings and the

magnets.

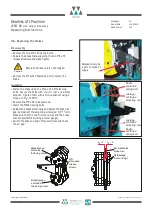

Lift machines are generally equipped with rope slip-off

guards. After putting the ropes in place, adjust them so

that the distance between the rope and the rope slip-off

guard does not exceed 1.5 mm.

Seite/page

9

Datum/date

12.08.2016

Stand/version

0.18

6. Installation

Änderungen vorbehalten! Subject to changes without notice!

Danger

Note

Warning

Note

Note

0,6

0,7

0,8

0,9

1,0

1,1

1,2

0

10

20

30

40

50

60

Ambient temperature [°C]

Fa

ct

or

k

Altitude < 1000 m

Altitude < 2000 m

Altitude < 3000 m

Danger

Warning

Summary of Contents for Beamer 2 Series

Page 36: ......

Page 37: ......

Page 41: ......