Maintenance

2722

−

1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

Tools:

Key to Illustrations:

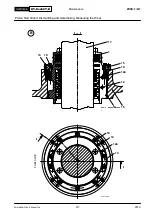

1 Protection cap

94271

1 Injection valve

14 Nozzle body

1 OBEL test bench

94272

2 Allen screw

15 Retaining sleeve

1 Connecting piece

94272b

3 Spring plate

16 Snap ring

4 Cup spring packet

17 Dowel pin

5 Nozzle holder

18 Dowel pin

6 Collar nut

19 Cylinder cover

7 Spring tensioner

20 Support

8 Nozzle tip

21 HP hose

9 O-ring

22 Receiver

10 Tappet

23 Dowel pin

11 Retaining nut

24 Spring cage

12 Compression spring

13 Nozzle needle

LF Leakage fuel

Overview

1.

General

1/8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

Checking an injection valve

2/8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

Judging an injection valve

3/8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

Dismantling an injection valve

4/8

. . . . . . . . . . . . . . . . . . . . . . . . . .

5.

Assembling an injection valve

4/8

. . . . . . . . . . . . . . . . . . . . . . . . . .

6.

Adjusting the opening pressure

6/8

. . . . . . . . . . . . . . . . . . . . . . . . .

7.

Replacing a nozzle tip

6/8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.

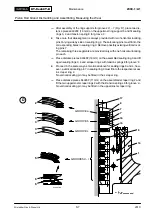

Arrangement of cup spring packet

7/8

. . . . . . . . . . . . . . . . . . . . . .

9.

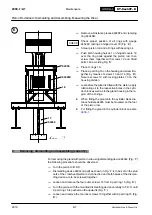

Fitting an injection valve in cylinder cover

7/8

. . . . . . . . . . . . . . .

10.

Protecting a nozzle tip

8/8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.

Storage and handling of injection valve

8/8

. . . . . . . . . . . . . . . . . .

1.

General

For checking, dismantling, assembling and adjusting the injection valve, test

bench 94272 as well as test & calibration fluid has to be used (e.g. Shell Calibration

Fluid S.9365) complying with the data according to the following table:

Physical characteristics for test & calibration fluid:

Kinematic Viscosity

ASTM D445

at 40

_

C

mm

2

/s

2.6

Density at 15

_

C

kg/m

3

ISO 12185

827

Pour Point

_

C

ISO 3016

−

27

Remark:

Clean diesel oil (gas oil) can be used if no calibration fluid is available.

The use however is not recommended, if the injection valve will be stored and not

directly installed on the engine (corrosion reasons).

On some injection valves the leakage flow amount might be bigger than on others.

In case of the test bench flow is not sufficient to open the nozzle needle, a clean

additive-type crankcase (system) oil of the SAE 30 viscosity grade (for additional

data see 0750

−

1 ’System oil’ in the Operating Manual) can be used for testing

instead of the above mentioned fluids.

Injection Valve

Checking, Dismantling, Assembling and Adjusting

2013-08

Summary of Contents for WARTSILA RT-flex58T-D

Page 8: ...Intentionally blank ...

Page 10: ...Intentionally blank ...

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 20: ...Intentionally blank ...

Page 32: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 66: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 84: ...Intentionally blank ...

Page 88: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 122: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 132: ...Intentionally blank ...

Page 136: ...Intentionally blank ...

Page 148: ...Intentionally blank ...

Page 152: ...Intentionally blank ...

Page 156: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 176: ...Intentionally blank ...

Page 186: ...Intentionally blank ...

Page 192: ...Intentionally blank ...

Page 196: ...Intentionally blank ...

Page 200: ...Intentionally blank ...

Page 214: ...Intentionally blank ...

Page 234: ...Intentionally blank ...

Page 238: ...Intentionally blank ...

Page 242: ...Intentionally blank ...

Page 256: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 272: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 282: ...Intentionally blank ...

Page 290: ...Intentionally blank ...

Page 296: ...Intentionally blank ...

Page 300: ...Intentionally blank ...

Page 312: ...Intentionally blank ...

Page 314: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 334: ...Intentionally blank ...

Page 340: ...Intentionally blank ...

Page 348: ...Intentionally blank ...

Page 352: ...Intentionally blank ...

Page 356: ...Intentionally blank ...

Page 358: ...Intentionally blank ...

Page 362: ...Intentionally blank ...

Page 366: ...Intentionally blank ...

Page 370: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 384: ...Intentionally blank ...

Page 386: ...Intentionally blank ...

Page 392: ...Intentionally blank ...

Page 402: ...Intentionally blank ...

Page 412: ...Intentionally blank ...

Page 414: ...Intentionally blank ...

Page 438: ...Intentionally blank ...

Page 440: ...Intentionally blank ...

Page 444: ...Intentionally blank ...

Page 454: ...Intentionally blank ...

Page 498: ...Intentionally blank ...