Maintenance

1224

−

1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

Tools:

Key to Illustrations:

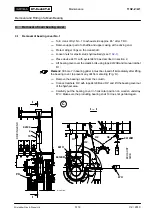

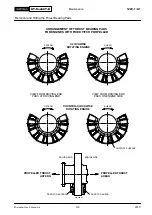

1 Turning-out device

94155

1 Thrust bearing flange

5 Screws with locking

for engines with

2, 2a Thrust bearing pads

plates

1-part gear wheel

3 Gear wheel

6 Bearing cover

1 Turning-out device

94155A

on thrust bearing flange

7 Oil baffle, upper part

for engines with

4 Holder

2-part gear wheel

1 Eye bolt M16

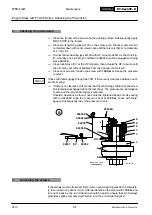

1.

Removal

⇒

Remove screws 5 to both holders 4 (Fig. ’A’).

⇒

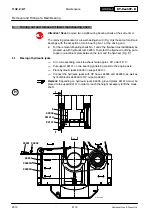

In addition, to ensure a better access for the removal of thrust bearing pads 2

(ASTERN operation), the upper part of oil baffle 7 (Fig. ’B’) is also to be re-

moved (see

⇒

Insert and laterally fasten turning-out device 94155 or 94155A as illustrated

on Fig. ’B’.

⇒

The crankshaft is then to be turned with the turning gear until an eye bolt M16

can be screwed into a pad which can then be lifted up and removed one by

one.

Remark:

When only a few thrust bearing pads of a row are to be removed the

crankshaft is located in its axial position by the remaining pads. When all thrust

bearing pads must be removed then the crankshaft must be prevented from sliding

axially. Therefore, insert a piece of hardwood of the same thickness in place of the

thrust bearing pad.

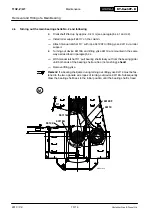

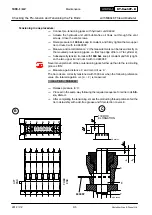

2.

Fitting

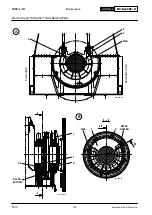

Make absolutely sure that all the thrust bearing pads are meticulously clean and

smeared with fresh engine oil; the thrust bearing pads must all be replaced in their

original position. Note the numbering of the individual pads! Also refer to the follow-

ing pages for the arrangement of thrust bearing pads on engines with fixed pitch

propellers (F.P.P.) and controllable pitch propellers (C.P.P.) respectively.

For fitting the thrust bearing pads tools 94155 or 94155A respectively can also be

utilized. Note in this respect that the first pad, when pushed in, rests against the

tool. The following thrust bearing pads can then be fitted one after the other while

simultaneously turning the crankshaft. The thrust bearing pads should slide in

without effort to their end position.

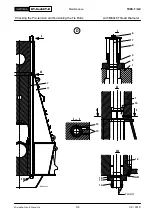

With all the thrust bearing pads in position the distances from the outermost pads

on the fuel side and on the exhaust side to the upper edge of the bedplate must be

equal. The holders 4 can now be refitted. Subsequently check the clearance be-

tween holder and thrust bearing pads 2 and 2a (see Clearance Table

’Crankshaft and thrust bearing’).

Attention!

After fitting the thrust bearing pads immediately remove tool 94155 or

94155a respectively.

Remark:

When fitting new or remetalled thrust bearing pads, care must be taken

that their thickness (final dimension) corresponds exactly with the neighboring

pads.

When replacing a complete row of new or remetalled thrust bearing pads the clear-

ance must be adjusted to the original values (see Clearance Table 0330

−

1 ’Crank-

shaft and thrust bearing’ and

Thrust Bearing

Removal and Fitting the Thrust Bearing Pads

2013

CHECK

Summary of Contents for WARTSILA RT-flex58T-D

Page 8: ...Intentionally blank ...

Page 10: ...Intentionally blank ...

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 20: ...Intentionally blank ...

Page 32: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 66: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 84: ...Intentionally blank ...

Page 88: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 122: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 132: ...Intentionally blank ...

Page 136: ...Intentionally blank ...

Page 148: ...Intentionally blank ...

Page 152: ...Intentionally blank ...

Page 156: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 176: ...Intentionally blank ...

Page 186: ...Intentionally blank ...

Page 192: ...Intentionally blank ...

Page 196: ...Intentionally blank ...

Page 200: ...Intentionally blank ...

Page 214: ...Intentionally blank ...

Page 234: ...Intentionally blank ...

Page 238: ...Intentionally blank ...

Page 242: ...Intentionally blank ...

Page 256: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 272: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 282: ...Intentionally blank ...

Page 290: ...Intentionally blank ...

Page 296: ...Intentionally blank ...

Page 300: ...Intentionally blank ...

Page 312: ...Intentionally blank ...

Page 314: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 334: ...Intentionally blank ...

Page 340: ...Intentionally blank ...

Page 348: ...Intentionally blank ...

Page 352: ...Intentionally blank ...

Page 356: ...Intentionally blank ...

Page 358: ...Intentionally blank ...

Page 362: ...Intentionally blank ...

Page 366: ...Intentionally blank ...

Page 370: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 384: ...Intentionally blank ...

Page 386: ...Intentionally blank ...

Page 392: ...Intentionally blank ...

Page 402: ...Intentionally blank ...

Page 412: ...Intentionally blank ...

Page 414: ...Intentionally blank ...

Page 438: ...Intentionally blank ...

Page 440: ...Intentionally blank ...

Page 444: ...Intentionally blank ...

Page 454: ...Intentionally blank ...

Page 498: ...Intentionally blank ...