3.7 The LED displays

when the dryer is operating

YES

Check if the bottle is full

Empty the bottle

NO

YES

Check if the pump is connected correctly

Attach

the

terminals accordingly or replace the loom

Check PCB for any signs of damage

Check connections on PCB and replace if necessary

NO

YES

Check if the pump is damaged or blocked

Replace or clean the pump

NO

YES

Check if the water level sensor is damaged

Replace the water level sensor

3.8 Error warning codes

Error ‘code’

Error description

Parts to check

Bottle full

indicator lit

Bottle is full of water

and bottle full indicator is lit

Check the water container, pump and water level

sensor

E30 Heater

not

working

Check the heater and motor

Clean filter

indicator lit

Filter mesh is blocked

Clean the filter mesh and restart the machine

E32

Load moisture sensor not

working

Check the moisture sensors and restart the machine

E33

Inlet thermistor not functioning

correctly

Check the inlet thermistor (on heater assembly) and

check associated connections

E34

Exhaust thermistor not

functioning correctly

Check the exhaust thermistor (below filter) and check

associated connections

4.1 Disassembly warnings

The mains cable must be disconnected from the power supply when disassembling or repairing the

machine.

The loom harness and terminals used must be for the correct wire size and the correct tools must be

used to crimp any terminals onto the harness. Insulation tape must be used where appropriate.

When attaching terminals to the mating connectors, always ensure that they are pushed fully on.

When attaching a wire via a screw terminal, ensure that sufficient wire is underneath the screw

terminal. Ensure that the screw is tightened satisfactorily.

The loom harness should not touch any moving parts or sharp edges. The wiring route around high

temperature objects (e.g. motor) should be followed as per the initial construction.

Always use the specified screws

Summary of Contents for B96M8W

Page 14: ...Exploded View Base ...

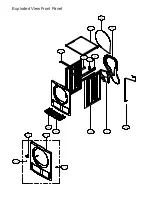

Page 15: ...Exploded View Front Support ...

Page 16: ...Exploded View Control Panel Water Bottle ...

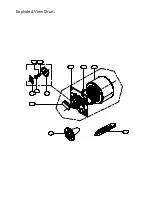

Page 17: ...Exploded View Drum ...

Page 18: ...Exploded View Front Panel ...

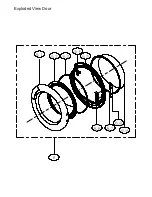

Page 19: ...Exploded View Door ...