73

WHL-016 REV. 12.18.14

NOTE:

The boiler will automatically exit test mode after 20 minutes of operation.

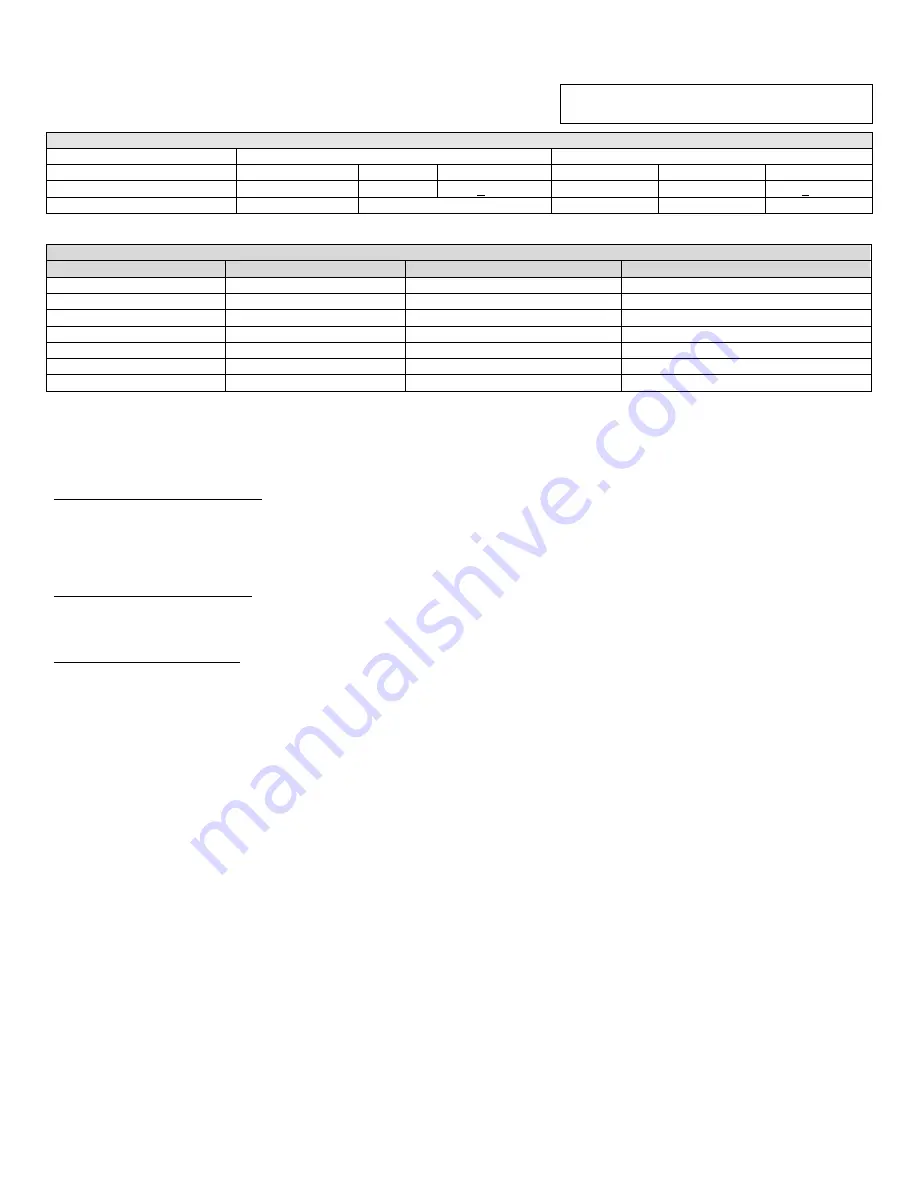

COMBUSTION SETTINGS ON ALL MODELS

Natural Gas

Propane LP

Fan Speed

Low

Ignition

High

Low

Ignition

High

Carbon Monoxide PPM

5

– 50

60 - 100

< 150

5

– 50

60 - 100

< 150

Carbon Dioxide (CO

2

)

8 - 10%

8 ½ - 10 ½%

8 ½ - 10 ½%

9 - 10 ½%

9 ½ - 11%

Table 27

FAN SPEEDS

MODEL

IGNITION

MIN

MAX

055

3800

1650

4050

080

3800

1850

5000

110

3800

1850

6050

155

4100

1850

5400

199

3800

1750

6050

285

4600

1800

6050

399

4200

1900

6950

Table 28

PART 12 – SHUTDOWN

A. SHUTDOWN PROCEDURE

If the burner is not operating, disconnect the electrical supply.

If the burner is operating, lower the set point value to 70

o

F and wait for the burner to shut off. Continue to wait for the combustion

blower to stop, so all latent combustion gases are purged from the system. This should take a maximum of 40 to 90 seconds.

B. VACATION PROCEDURE

If there is danger of freezing, change the set point to 70

o

F. DO NOT turn off electrical power. If there is no danger of freezing, follow

“Shutdown Procedure”.

C. FAILURE TO OPERATE

Should the burner fail to light, the control will perform two more ignition trials prior to entering a lockout state. Note that each

subsequent ignition trial will not occur immediately. After a failed ignition trial, the blower must run for approximately 10 seconds to

purge the system. Therefore, a time period of approximately 40 to 90 seconds will expire between each ignition trial.

If the burner lights during any one of these three ignition trails, normal operation will resume. If the burner lights, but goes off in about 4

seconds, check the polarity of the wiring. See electrical connection section.

If the burner does not light after the third ignition trial, the control will enter a lockout state. This lockout state indicates that a problem

exists with the boiler, the controls, or the gas supply. Under such circumstances, a qualified service technician should be contacted

immediately to properly service the boiler and correct the problem. If a technician is not available, depressing and holding the RESET

button for more than 1 second will remove the lockout state so additional trials for ignition can be performed. The unit will try to re-light

once every 6 minutes.

SERVICE RUN

3400 RPM

PUMP ON

4:49P

Summary of Contents for WBCNG399W

Page 14: ...14 WHL 016 REV 12 18 14 SPECIFICATIONS AND DIMENSIONS Figure 2 Specifications and Dimensions ...

Page 24: ...24 WHL 016 REV 12 18 14 Figure 8 Piping Symbol Legend ...

Page 59: ...59 WHL 016 REV 12 18 14 Figure 32 Cascade Master and Follower Wiring ...

Page 60: ...60 WHL 016 REV 12 18 14 Figure 33 Internal Connection Diagram LP 293 J ...

Page 83: ...83 WHL 016 REV 12 18 14 055 080 110 PARTS BREAKDOWN Figure 36 Replacement Parts LP 387 J ...

Page 85: ...85 WHL 016 REV 12 18 14 155 199 285 399 PARTS BREAKDOWN ...

Page 86: ...86 WHL 016 REV 12 18 14 Figure 38 Replacement Parts LP 387 KK ...

Page 87: ...87 WHL 016 REV 12 18 14 155 199 285 399 MODEL PARTS BREAKDOWN ...

Page 91: ...91 WHL 016 REV 12 18 14 ...

Page 92: ...92 WHL 016 REV 12 18 14 ...