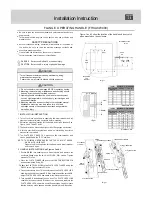

Figure. 1 and 2 show the location of the handle and door catch

when mounted on the enclosure.

FLANGE, OPERATING HANDLE (FHU ACW400)

<Fig. 3>

<Fig. 1>

-Dimensions : inch

(mm)

0.433

(11)

4.251

(108)

4.685

(119)

F

1 83

46.5

.

(

)

7.874

200

(

)

#

UNC

Tap

(4 Holes)

10-24

E

1. INSTALLATION INSTRUCTION

PLATEFLANGE LINK

M6X18

SCREW

PLATEASS'Y

FLANGE

O-RING

HANDLEASS'Y FLANGE

GROOVE

E-RING, D8

PLATELOCK FLANGE

M6X10 SCREW

PLATELOCK LINK

LINK CONNECTIONPIN

<Fig. 2>

F "UP"

F "DOWN"

E MAX

Installation Instruction

Be sure to read the instruction manual and safety precautions before

use products.

This manual should be given to the person who use products and

maintain them.

SAFETY PRECAUTIONS

Before installation, wiring, operation, maintenance or inspection of

the device, be sure to read the warning message carefully and

ensurance proper operation.

Please follow the instructions, they are very important.

In this instruction, level of danger is classified by

¤

¤

¤

¤

*

* Turn off the power before mounting,

, wiring,

maintenance or inspection.

Failure to do

may result in electric shocks and burns.

withdrawing

it

CAUTION

DANGER

1. Do not use deformed or damaged MCCB or operati

handle.

2. Mounting, removal, wiring, maintenance and checking should

be done by authorized or certified

.

3. Operati

handle should not be used in severe environment

such as high temperature, humidity, dusty, corrosive gas and

excessive vibration.

4. Mounting should be done according to the instruction manual.

Mistakes on mounting may be a cause for a

and

operation handle or cause an accident such as operator do

himself an injury.

ng

personnel

ng

ACW

DANGER

CAUTION

It may result in death or serious injury.

It may result in injury or physical damage.

2. HANDLE INSTALLATION-See Figures 3 and 4.

1. Turn off and lock out all power supplying the circuit breaker and all

other equipment within the enclosure before installing.

2. Determine mounting location for the handle and circuit breaker. See

Figure. 1 and Tables 1 and 2.

3. The handle can be mounted on right side of flange type enclosures.

4. A latch is provided for applications where no interlocking door latch

mechanism is provided.

5. The PLATE ASS'Y BASE FH-1 mounts to the circuit breaker and

can be padlocked in the "OFF"position.

1

. Secure O-RING into

groove. Mount handle and frame to the

enclosure flange using the two M6X18 (+)PH, P/W screws. Tighten

screws to 75 in-lbs.

2. Place the PLATE FLANGE LINK onto the LINK CONNECTION PIN

and secure with the E-ring, D8.

3. Attach the PLATE LOCK LINK to the PLATE LOCK FLANGE using the

M6X10 screw. Tighten nuts to 25 in-lbs.

4. Close the enclosure door. This should release the PLATE LOCK LINK

allowing the handle to be turned ON. If the handle cannot be turned ON,

adjust PLATE HOOK LOCK downward in its slot and repeat item 4.

5. Turn handle ON and attempt to open door. The PLATE LOCK LINK

should hold the door closed. If the door can be opened, readjust the

PLATE HOOK LOCK upward in its slot. Repeat steps 3 and 4 to insure

that the door can not be opened when the handle is in the ON position.

handle

NOTE : THE MINIMUM BEND RADIUS FOR THE CABLE IS THREE&

ONE-HALF(3-1/2)INCHES.

Prepare the mounting holes for the handle and circuit breaker

and remove burrs.

TABLE1

MAXIMUM "E" DIMENSION

ENCLOSURE

DEPTH

FHU-60

FHU-72

TABLE2

MAXIMUM " " DIMENSION

F

ENCLOSURE

DEPTH

62 cable

72 cable

Dimensions : inch

Dimensions : inch

UP DOWN UP DOWN

8

PLATELOCK LINK