CHAPTER 9

• CLICK 514

107

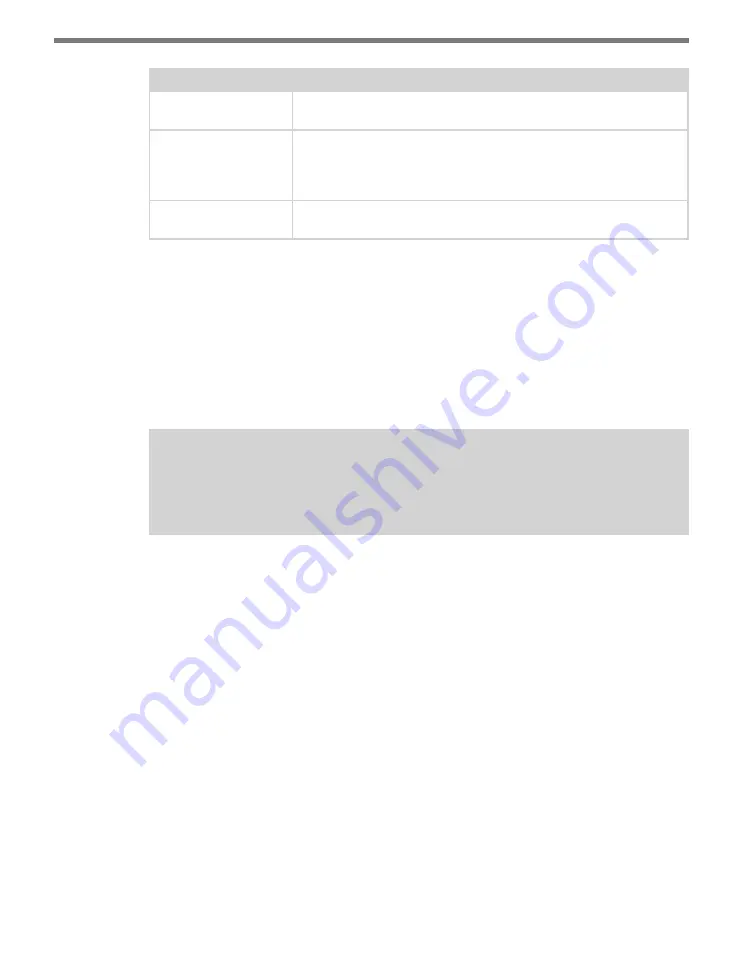

Setting

Description

Time Zone

Allows you to select the time zone for presentation of data. (Smart-

Sensor HD timestamps are natively in UTC time.)

File Time

Sets the duration of each log file in the recording session. The options

are hourly, daily or continuous. Continuous indicates that you simply

want to send all logged data to one file without segmentation every

hour or day.

Sensor ID

Allows you to enter the Sensor ID for the SmartSensor HD. The Sen-

sor ID is used for time synchronization.

Table 9.5 – Expert Driver Settings Tab

Once you have finished, use the menu bar at the top of the screen to save your settings,

return to the Select Driver screen, and more.

˽

The

Save

menu allows you to save your settings. Select

Save to File

to save your settings

to a file. Selecting this will open a directory box, allowing you to name your settings

file. This file will always be saved in the Wavetronix folder created when you installed

Click Supervisor, under Wavetronix > ClickHome > Drivers > 514 > User. You can also

select

Save to Device

to save your settings to your Click 514.

Note

If you do not save your settings to your Click 514, they will be lost the next time you

power the device down.

˽

The

Tools

menu contains five options for working with your device.

Reset > System

power cycles your device, while

Reset > Factory Default

restores your device to the

settings with which it was shipped.

Restore

will restore the driver to the settings cur-

rently saved on the Click 514, erasing any unsaved changes.

Upgrade

can be used to

manually upgrade to the most current firmware for your device.

Hex View

changes the

view of certain settings in the driver to hexadecimal.

˽

Clicking the

Quit

menu exits the driver and returns you to the Click Supervisor main

page.

Summary of Contents for Click 500 Series

Page 1: ...Click 500 Series USER GUIDE...

Page 9: ......

Page 15: ......

Page 37: ......

Page 39: ......

Page 75: ......

Page 93: ......

Page 109: ...www wavetronix com...