IS-15M2

Water Hammer Arrestors

Sizes:

1

⁄

2

" – 1" (15 – 25mm)

Available in All PDI Unit Sizes A – F

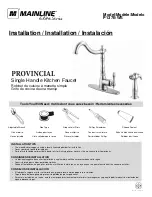

Fig. 1

Shock

Source

Fig. 2

Shock

Source

May be Installed in

a Horizontal Position

Sizes:

1

⁄

2

" NPT - SIZE A 15mm

3

⁄

4

" NPT - SIZE B 20mm

1" NPT - SIZE C 25mm

1" NPT - SIZE D 25mm

1" NPT - SIZE E 25mm

1" NPT - SIZE F 25mm

Sizes:

1

⁄

2

" Solder - SIZE A 15mm

3

⁄

4

" Solder - SIZE B 20mm

1" Solder - SIZE C 25mm

1" Solder - SIZE D 25mm

1" Solder - SIZE E 25mm

1" Solder - SIZE F 25mm

Series 15M2 and LF15M2

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can

result in death, serious personal injury, property damage, or

damage to the equipment.

Keep this Manual for future reference.

1. Install as close to shock source as possible.

2. Install a shock arrestor on both hot and cold lines.

3. Best results are obtained when installed as shown in Figure 1

or Figure 2. They can be installed in concealed locations with-

out access panels.

Operating Pressure

Designed to operate on all domestic and commercial lines at

150psi (10.3 bar) working pressure. Systems which exceed

60psi (414 kPa) shall be installed with a pressure reducing valve

upstream of the unit.

Temperature Range

33°F to 180°F (0.5°C to 82°C)

Installation

May be installed in new or existing plumbing systems with a stan-

dard pipe tee vertically, horizontally or at any angle. Series 15M2

and LF15M2 are factory air charged and permanently sealed. They

may be installed in concealed locations without access panels and

are not rechargeable in the field.

Standards

A.S.S.E. 1010 Approved

ANSI A112.26.1M Approved

Listed by UPC

P.D.I. WH201 Approved & Certified

Installation