Operating Instructions

WX900 Series

Log Splitter

22

•

Store fuel away from all wood material.

•

Only operate the engine in a location that has good air

flow. Engine exhaust gases contain carbon monoxide (an

odorless gas) that can cause asphyxiation.

•

Do not put your hands or feet near moving parts.

•

Do not choke the carburetor to stop the engine. Whenever

possible, gradually reduce the engine speed before

stopping.

•

Do not tamper with governor springs, governor links or

other parts that may increase the governed speed. Engine

speed is selected by the original equipment manufacturer.

•

Do not check for a spark with the spark plug or spark plug

wire removed.

•

Do not attempt to start the engine with the spark plug

removed. If the engine floods, set the choke control to

Open

, set the throttle control to

Fast

, and then try starting

the engine again.

•

Do not hit the flywheel with a hard object or metal tool. This

can cause the flywheel to shatter during operation. Use the

correct tools to service the engine.

•

Do not touch a hot muffler, cylinder, or fins. Contact may

cause burns. Wait for the machine to cool. Use a no-touch

thermometer to measure the temperature.

•

Do not operate the engine in any of the following situations:

-

With an accumulation of wood chips, dirt, or other

combustible materials in the muffler area.

-

In an area where fuel is spilled. Move the machine away

from the spill until the fuel evaporates. Do not create

any sources of ignition in the spill area.

-

With the air filter or air filter cover removed. Doing this

can damage the engine.

-

Without a muffler or heat shield. Inspect the muffler and

heat shield periodically. Replace a damaged muffler or

heat shield.

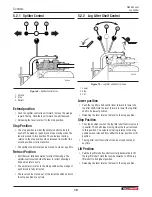

6.5.2 Check the Engine Oil Level

IMPORTANT! For more information about engine oil, see

the engine manufacturer's manual and

Operating the engine with a low oil level can cause engine

damage that is not covered by the warranty.

The engine must be in a level position for the

dipstick to show the oil level correctly.

Check the engine oil level before each use.

1.

Park the machine on level ground.

2.

Stop the machine.

For instructions, see

.

3.

Remove the oil-level dipstick and clean it.

4.

Fully insert the oil-level dipstick.

5.

Remove the oil-level dipstick and check the oil level.

The oil level is correct when the oil is visible on the dipstick

from the end to the full (upper) mark.

6.

Do one of the following:

-

If the oil level is correct, continue with step 7.

-

If the oil level is low, add oil until the oil-level is at the

full (upper) mark. For instructions, see

7.

Install the oil-level dipstick and make sure that it is tight.

02045

Figure 11 –

Check the engine oil level

Summary of Contents for WX900 Series

Page 48: ...WallensteinEquipment com...