To Lower the Conveyor Angle

•

Turn the winch handle counterclockwise. No clicking sound

is heard because the brake system is activated.

00448

Fig. 12 –

Lowering Conveyor

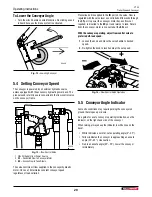

5.4 Setting Conveyor Speed

The conveyor is powered by an external hydraulic source,

unless equipped with the accessory hydraulic power pack. The

pressure and return lines are connected to the flow control valve

on the conveyor frame.

00530

Fig. 13 –

Flow Control Valve

1.

IN

– Oil Supply from Power Source

2.

CF

– Controlled Flow to Conveyor Motor

3.

EX

– Excess Flow to Tank Return

The valve controls oil flow supplied to the conveyor hydraulic

motor. Once set, it maintains constant conveyor speed

regardless of load variation.

Pressurized oil is supplied to the

IN

port on the valve. Flow is

regulated with the valve lever so controlled oil flow exits through

the

CF

port to power the conveyor motor. Excess flow not

required, is diverted to the

EX

port and returns to tank. Return

from the conveyor motor is connected at the

EX

port.

With the conveyor operating, adjust flow control valve to

preferred off-load speed.

1.

Loosen the knob and move the valve handle to desired

speed.

2.

Re-tighten the knob to lock handle at the set speed.

–

+

00470

Fig. 14 –

Flow Control Valve Operation

5.5 Conveyor Angle Indicator

Some site conditions may require parking the conveyor on

ground that slopes up or down.

As a guide for a safe conveyor operating inclination, use the

indicator on the right-hand side of the conveyor

When raising, always keep the indicator in white zone on the

decal.

•

White indicates a normal, safe operating angle (0°–35°).

•

Yellow indicates the conveyor is approaching an unsafe

angle (35°–45°). Use caution.

•

Red is an unsafe angle (45°–55°). Lower the conveyor

immediately.

Operating Instructions

CT24

Trailer Firewood Conveyor

20