46

BXTR6438

5.5 Maintenance

By following a careful service and maintenance pro

-

gram for your machine, you will enjoy many years

of trouble-free operation.

Put the machine in

safe condition

before working

on this machine,

•

shut off the engine.

• ensure all components have stopped moving.

• remove and pocket the ignition key.

• disconnect the battery.

• block and chock the wheels.

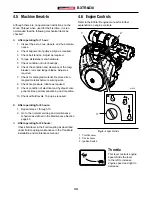

5.5.1 Kohler CH980 38HP Engine

For periodic service, review your engines

instruction manual for specific instructions /

requirements for:

• Oil

•

Oil filter

• Air cleaner

•

Fuel filter

• Fuel lines

In order to make the process of changing oil easier

an oil drain extension has been added and is located

at the rear of the machine.

5.5.2 Hydraulic Oil Fill

The BXTR6438 hydraulic tank is located next to

the fuel tank and is equipped with a site glass that

shows the level of the oil in the tank. (located just

above the tool box lid)

Hydraulic oil level should be checked daily, and the

quality of the oil should be inspected every 50 hr. If

the oil is dirty or smells burnt, it should be replaced.

For optimum performance, the filter should be

changed every 100 hr, and the hydraulic oil should

be changed every 500 hr or once a year.

1.

Allow the engine and muffler to cool.

2.

Clean area around fill cap and remove cap.

3.

Using a clean funnel, fill the tank according to

the oil level gauge:

•

When filling the tank with oil, the window of

the site glass will also fill with oil as the level

gets higher in the tank.

•

Never fill the oil tank above the

site glass.

• Do not run the machine with the oil level below

the

site glass.

• Reservoir Capacity 30 L. (7 US Gal.)

• Use Dexron III hydraulic oil for all operating

conditions.

4.

Install fill cap securely and wipe up any spilled

oil.

Check levels after changing filters or servicing hy-

draulic components.

Hydraulic Oil Level

Hydraulic Site Glass

Engine Oil Drain

Location