Service and Maintenance

BXM32, BXM42

3-point Hitch Chipper-Shredder

40

00910

4

Fig. 37 –

BXM42 Rotor PTO Bearings

00911

5

5

Fig. 38 –

BXM42 Rotor Bearings

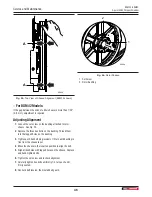

9.4 PTO Shaft Maintenance

Grease the PTO shaft every 8 hours.

00584

Fig. 39 –

PTO Shaft

The PTO shaft is designed to collapse and extend as the

machine goes through its operational range.

Heavy-duty plastic shielding encloses the driving components.

As a safety measure, it is designed to stay stationary as the

driveshaft turns.

Annual disassembly, cleaning and inspection is recommended

to make sure that all components function as intended.

Shear Pin

The PTO shaft has a shear pin on the implement end, at the

input yoke. The shear pin is designed to break in the event the

drive system is overloaded to protect other critical components.

00870

Fig. 40 –

PTO Shear Pin

The drive system is designed to function well without the shear

pin failing. If it does fail, generally it is because material is being

fed too fast or something very hard has been jammed into the

rotor or between the blades.