Attach to a Tractor

BXS Series

3PH Self-feed Chipper

18

5. Attach to a Tractor

Make sure the telescoping portion of the PTO shaft is

greased and free of dirt.

The BX36S and BX52S lower ski is adjustable. Ski

adjustment may be required to help make the PTO

connection as level as possible. See Machine Setup

on page 26.

5.1 Connect 3-point Hitch

WARNING!

Never let anyone stand between the tractor and

the implement during hitching. Too fast of an

approach or the operator’s foot slipping from the

clutch can lead to injury or fatality to the person

standing nearby.

W048

IMPORTANT! Removing the drawbar may be required for

clearance.

For maximum PTO shaft life and safety, the PTO shaft should

be as level as possible when the chipper is in the working

position. See

•

The BX36S, BX52S and BX72S are Category I, 3-point

hitch, and Quick Hitch and iMatch™ compatible.

•

BX102S is Category II, 3-point hitch only, and is also Quick

Hitch and iMatch™ compatible.

Make sure there is enough room and clearance to safely reverse

to the chipper.

Procedure

1.

On the tractor, place the 3-point hitch lift arms in their full

sway position, then reverse the tractor up to the chipper.

The tractor needs to be exactly in-line with the mounting

points of the chipper otherwise attaching the 3-point hitch

may require moving the implement from side to side.

2.

When reversing, lower/raise the lift arms so that they are

level with the lower attachment points on the chipper.

00825

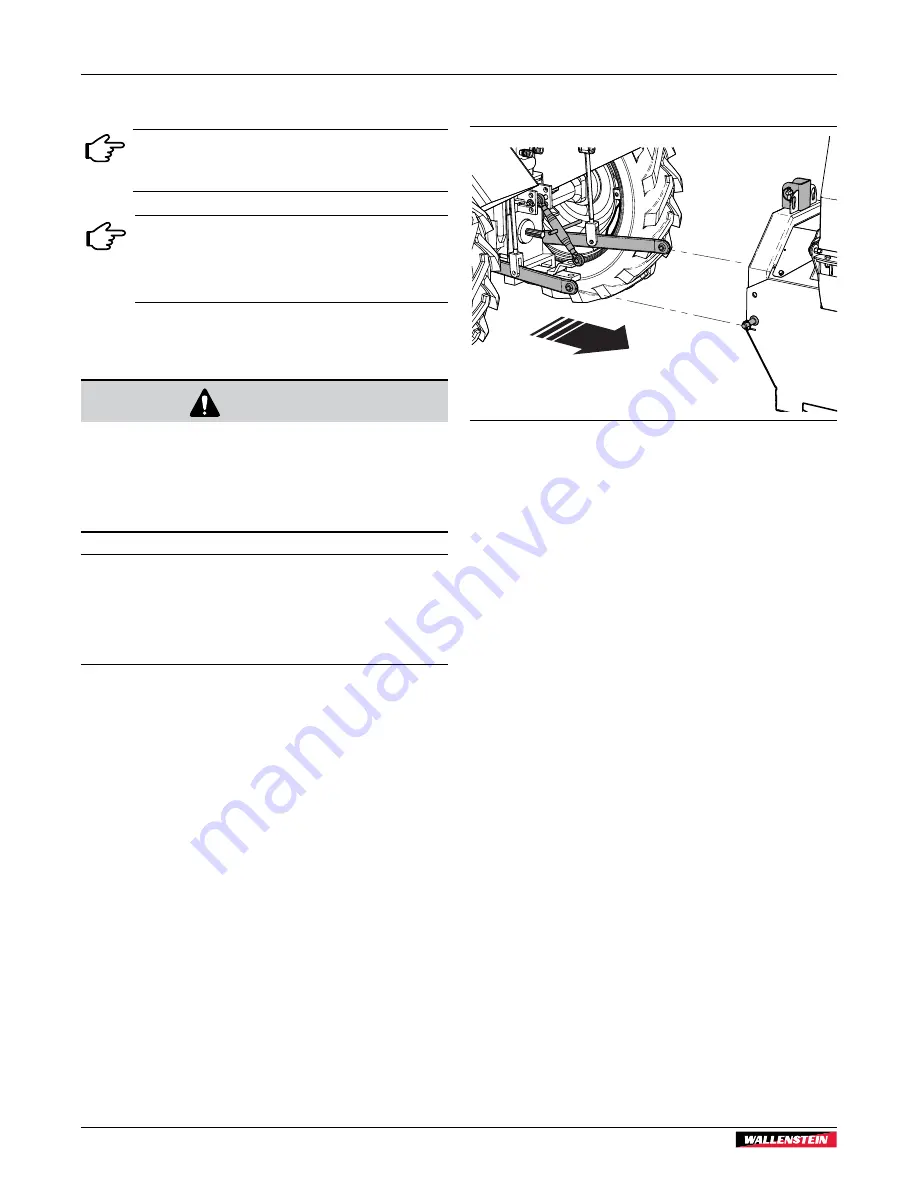

Fig. 7 –

Back up in line with the chipper

3.

Back up slowly and align the balls in the lift arms to the

pins on the chipper.

4.

Apply the tractor park brake.

5.

Starting on one side, push the floating ball on the tractor's

lift arms over the lower attachment pin on the chipper.

6.

Do the other side in the same manner, keeping the lift arms

even. Insert lynch pins on both sides to secure the chipper

to the tractor.

7.

Attach the tractor top link to the upper attachment point on

the chipper. Insert the pin and lynch pin.

8.

As with any implement, the turnbuckle on the top link

may need to be adjusted to level the chipper. Raise the

implement just off the ground to check. Adjust top link

length as required.

9.

If not already done, level the chipper from side to side using

the lift arm jack-screw arm and the top link turnbuckle.

The chipper frame should always be kept horizontal during

operation.