Assembly Instructions

B23

20

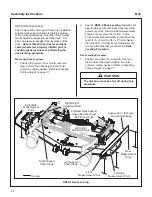

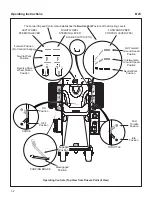

Deck Discharge Deflector Shield Installation

(Side Discharge Models Only)

Attach the side discharge deflector shield using

two (2) 3/8-16 x 1-1/4 in. bolts, 3/8-16 ESNA nuts,

and 3/8 in. wave spring washers. The wave wash-

ers fit between the two hinging surfaces. Tighten

the nuts until the shield moves freely but is not

loose.

WARNING

DO NOT operate the machine without the

grass deflector shield attached and in the

lowest possible position.

Attach Shield

Deck Discharge Shield Installation

PTO Shaft Guard Installation

Position the shaft guard as shown and mount with

two (2) 1/4-20 x 1/2 in. bolts.

Attach

Guard

Carrier Frame

Tube Sockets

PTO Shaft Guard Installation

Tilt-Up Roller Wheel Installation

Mount the two (2) tilt-up roller wheels on the brack-

ets on the rear skirt of the deck housing using the

P/N 8490 axle bolt, 3/8 in. plain washer, 3/8 in.

wave spring washer (between bracket and wheel)

and 3/8-16 Whiz locknut. Tighten the axle bolt until

the wheel rolls freely, but is not loose.

Roller

Wheels

Roller Wheel Installation