WAGO-I/O-System 750

Mounting

63

750-370 PROFINET IO Fieldbus Coupler

Manual

Version 2.0.0

5.3.2

WAGO DIN Rail

WAGO carrier rails meet the electrical and mechanical requirements shown in the

table below.

Table 29: WAGO DIN Rail

Order number Description

210-113 /-112

35 × 7.5; 1 mm; steel yellow chromated; slotted/unslotted

210-114 /-197

35 × 15; 1.5 mm; steel yellow chromated; slotted/unslotted

210-118

35 × 15; 2.3 mm; steel yellow chromated; unslotted

210-198

35 × 15; 2.3 mm; copper; unslotted

210-196

35 × 8.2; 1.6 mm; aluminum; unslotted

Pos: 60.6 /Serie 750 (WAGO-I/O-SYST EM)/M ontieren/D emontieren/Abstände @ 3\mod_1225448283750_21.docx @ 24920 @ 2 @ 1

5.4

Spacing

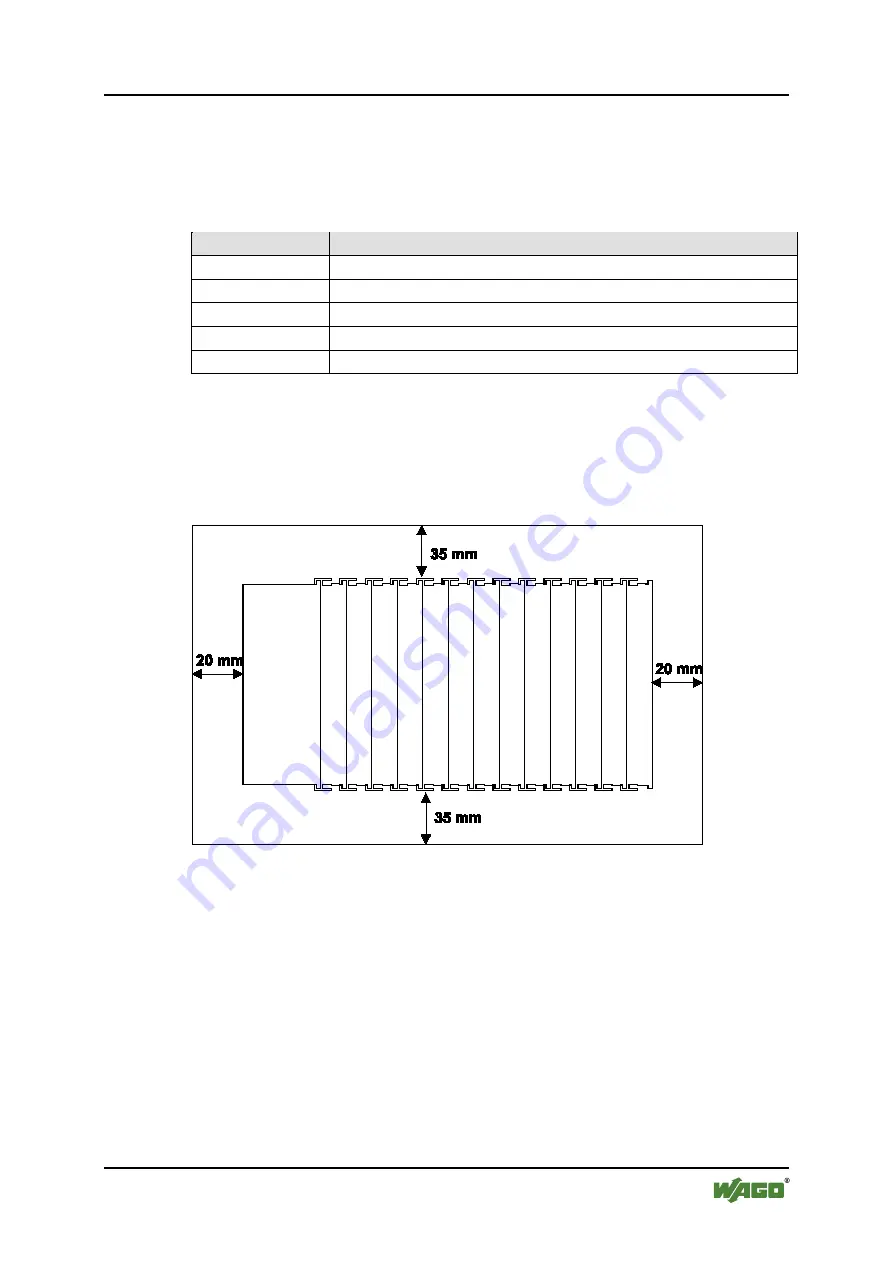

The spacing between adjacent components, cable conduits, casing and frame sides

must be maintained for the complete fieldbus node.

Figure 27: Spacing

The spacing creates room for heat transfer, installation or wiring. The spacing to

cable conduits also prevents conducted electromagnetic interferences from

influencing the operation.

Pos: 60.7 /Dokumentation allgemei n/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1