23

VERSION 01/2018

ORDER NUMBER DOC 2385674

TOPFINISH Bell 1S

5.2.2 ATOMIZATION PROCESS

5.2.2.1 SPRAYING PROCESS

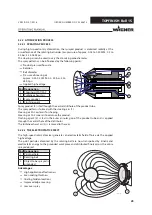

During high-speed rotary atomization, the sprayed product is atomized radially at the

circumference of the rotating bell under low-pressure of approx. 0.03 to 0.40 MPa; 0.3 to

4.0 bar; 4.35-58.02 psi.

The steering air can be used to vary the atomizing cone diameter.

The spray pattern can be influenced by the following points:

Product pressure/flow rate

Rotation

Bell diameter

Pressure of steering air

approx. 0.03–0.40 MPa; 0.3–4.0 bar; 4.35–

58.02 psi

Applied high voltage

Pos Designation

1 Steering air SA1/SA2

2 Turbine exhaust air

3 Spray product

4 Flushing agent

B_06634

1

3

4

1

2

Spray product (3) is fed through the central drill hole of the product tube.

The spray pattern is formed with the steering airs (1):

Steering air SA1: outer air for shaping.

Steering air SA2: inner air to advance the product.

Flushing agent (4) is fed in the outer annular gap of the product tube and is applied

through the central hole of the distributor.

The turbine exhaust air (2) is removed to the rear.

5.2.2.2 THE ELECTROSTATIC EFFECT

The high-speed rotary atomizer generates an electrostatic field of force via the applied

high voltage.

The paint particles atomized by the rotating bell are now transported by kinetic and

electrostatic energy to the grounded work piece and distributed finely across the entire

sprayed object.

Pos Designation

1 Paint particle

2 Rotating bell

3 Object to be sprayed is

grounded

Advantages:

High application effectiveness

Even coating thickness

Coating hidden locations

Improved edge covering

Low over spray

3

2

1

B_01137