19

Maintenance

7 Maintenance

During normal operation the OptiFlow

TM

Tail system must be checked for visible damage.

All maintenance measures are required over the entire service life of the components and should be

carried out at 6 month intervals.

Gas springs

– Check the gas springs

(B)

for ease of movement.

– Check if the panels

(2)

fit closely on the trailer without a gap.

Lifting rod

– Check the correct function of the top panel

(1)

by operating the lifting rod via the lever

(A)

. Check

the mechanism for ease of movement.

Ö

The lifting rod

(2)

must be connected to the top panel

(1)

.

Ö

If the lever

(A)

does not engage correctly, the clip lock may need to be replaced

– Check if the position of the lifting rods

(3)

is vertical and the connected crossbar to the top panel

(1)

is not deformed.

Ö

Check the positioning of the door bracket to avoid further damage.

Stopper

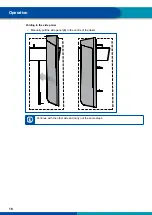

– Check the correct alignment of the side panels

(2)

.

Ö

The installed side panels

(2)

must run parallel to the outer edge.

Ö

If you have identified a misalignment, align the side panels

(2)

correctly using the stopper by

adjusting the distance to the trailer’s outer edge,

section „Mechanics and alignment“, page

Fine adjustment of the stopper:

– Check if the rubber element is attached to the stopper.

– Re-tighten the torque (M8 screw – 10 +/-2 Nm).

Rust may develop on some components but will not impair the function.

Summary of Contents for OptiFlow Tail

Page 1: ...INSTALLATION MANUAL...

Page 2: ......

Page 21: ...21 Spare parts...

Page 22: ...Notes 22...

Page 23: ......